Many buyers pick the wrong VFD — leading to system inefficiency, high energy bills, and equipment failures. But with the right selection method, you can avoid costly mistakes and ensure smooth, reliable operations.

To select the best variable frequency drive (VFD), assess installation environment, motor specs, torque needs, motor type, duty cycle, speed regulation, and application — ensuring optimal energy use, performance, and lifespan.

Want to maximize your inverter VFD investment? Read on to uncover critical selection insights that save money and boost system reliability.

What Is a Variable Frequency Drive, and Why Does It Matter?

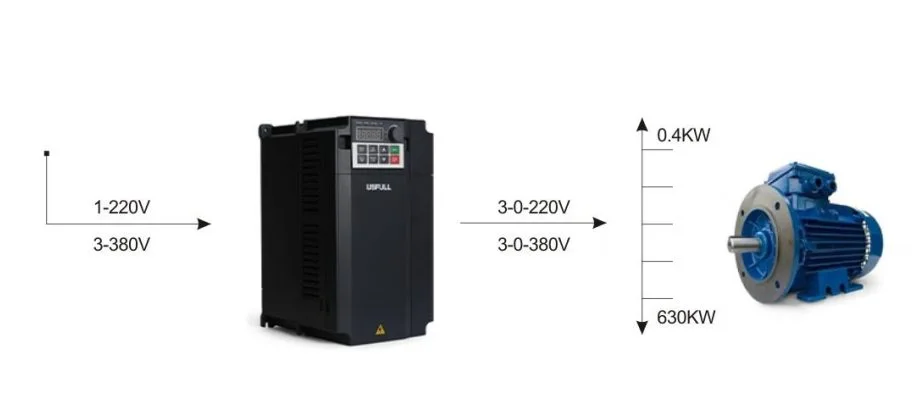

A variable frequency drive (VFD) — also called a frequency inverter, variable speed drive (VSD), or variable frequency inverter — is an electronic device that controls an AC motor’s speed and torque by varying input frequency and voltage.

By using a VFD, businesses can:

- Optimize motor performance

- Reduce energy consumption

- Improve process control

- Extend equipment life

Without a properly selected inverter VFD, motors may run inefficiently or even fail, leading to costly downtime. That’s why selecting the right variable frequency inverter is crucial for industries like manufacturing, agriculture, HVAC, water treatment, and more.

How Does the Installation Environment Impact VFD Selection?

Your VFD’s operating environment determines what enclosure type and protections you need.

For indoor installations, pay attention to:

- Ambient temperature (ensure cooling if necessary)

- Humidity and condensation risks

- Dust or corrosive chemicals in the air

For outdoor use, consider:

- Rain, snow, and direct sunlight exposure

- Temperature fluctuations

- Required IP rating for water and dust protection

For example, a variable frequency inverter in a food processing plant must handle washdowns, while a VFD installed outdoors on a farm pump system needs UV and weather protection. Choosing the wrong enclosure can lead to failures, so always match the drive to your environment.

Why Are Motor Ratings Critical When Selecting a VFD?

Matching your frequency inverter to your motor isn’t just about horsepower or kilowatts — you must consider the motor’s:

- Rated current (amps)

- Voltage (e.g., 220V, 380V, 440V)

- Frequency (50Hz or 60Hz)

A mismatched variable speed drive can cause underperformance, overheating, or tripped protections.

Also, ensure the inverter VFD matches the incoming power supply (single-phase or three-phase). When selecting for multiple motors or complex setups, work closely with your supplier to ensure compatibility.

What Are Torque Requirements, and How Do They Affect Your Choice?

Different applications have different torque demands:

- Constant torque: conveyors, crushers, mixers

- Variable torque: fans, pumps, blowers

For constant torque loads, you need a VFD that can deliver full torque at low speeds. For variable torque, energy savings matter most, and the drive should handle fluctuating demands efficiently.

Also, check the inverter’s overload rating — can it handle start-up surges or sudden load spikes without shutting down? Always assess torque curves to ensure the selected variable frequency drive matches real-world demands.

Which Motor Types Work Best with a VFD?

Most AC induction motors pair well with a VFD, but some modern setups use:

- Permanent Magnet Synchronous Motors (PMSMs)

- Brushless DC motors

These require specially designed inverter VFD systems that handle unique control needs.

If you’re upgrading older motors or adding a frequency inverter to a new setup, verify motor compatibility. Not all variable speed drives work with all motor types, and using the wrong pairing can damage both components.

| Motor Type | VFD Required? | VFD Compatibility Notes |

| Induction Motor (Asynchronous) | Optional | ✅ Fully compatible with standard VFDs; widely used in industrial, agricultural, and HVAC applications |

| Permanent Magnet Synchronous Motor (PMSM) | Required | ✅ Requires VFDs with vector control; offers high efficiency and precise speed control |

| Brushless DC Motor (BLDC) | Required | ⚠️ Requires dedicated drive; not all VFDs are compatible |

| Synchronous Motor | Optional | ⚠️ Requires VFDs with encoder feedback or advanced vector control |

| Single-phase Motor | Optional | ⚠️ Not ideal for VFDs; limited compatibility, suitable for low-load applications |

| Servo Motor | Required | ❌ Not compatible with standard VFDs; needs a dedicated servo drive |

| Switched Reluctance Motor (SRM) | Required | ❌ Incompatible with standard VFDs; needs a specialized controller |

How Does Duty Cycle Influence the Right VSD?

The duty cycle describes how long your motor runs under different loads. For example:

Light-duty: short bursts, low load

Heavy-duty: long runs, frequent starts/stops, or high stress

A standard VFD may overheat under heavy-duty conditions, so check continuous and peak ratings. Also, consider the drive’s thermal management features (like built-in fans or heatsinks).

For high-cycling applications, like a factory press, you need a rugged variable frequency inverter with top-tier durability. For light-duty, like a farm irrigation pump, a simpler, cost-effective VSD may suffice.

Why Does the Application Type Matter in VFD Selection?

Every application has unique demands:

- Pumps and fans: prioritize energy efficiency and soft start

- Conveyor belts: require precise speed and torque control

- HVAC systems: need variable speed to match demand

- Crushers or mixers: demand constant torque and overload protection

USFULL’s VFDs, such as the FU9000D series, are designed to fit specific industry needs, from light commercial tasks to heavy industrial operations. Matching the variable frequency drive to your specific application ensures reliability, efficiency, and cost savings.

Final Thoughts: Get the Right VFD for Long-Term Success

Selecting the right variable frequency drive is more than matching specs — it’s about understanding your system, environment, and goals. By considering these seven factors, you ensure that your frequency inverter or variable speed drive delivers peak performance and efficiency.

USFULL offers a complete lineup of customizable inverter VFD solutions, backed by ISO9001, CE, IEC, TUV, and INMETRO certifications.