The hidden cost of belt conveyor inefficiency in coal washing plants leads to increased energy waste, equipment damage, and high maintenance—USFULL Variable Frequency Drives provide the solution.

Belt conveyors in coal washing plants suffer from inefficient operations, high maintenance costs, and operational risks—USFULL Variable Frequency Drives (VFDs) offer superior control, enhanced performance, and significant energy savings.

What Are the Challenges of Traditional Belt Conveyor Systems in Coal Washing Plants?

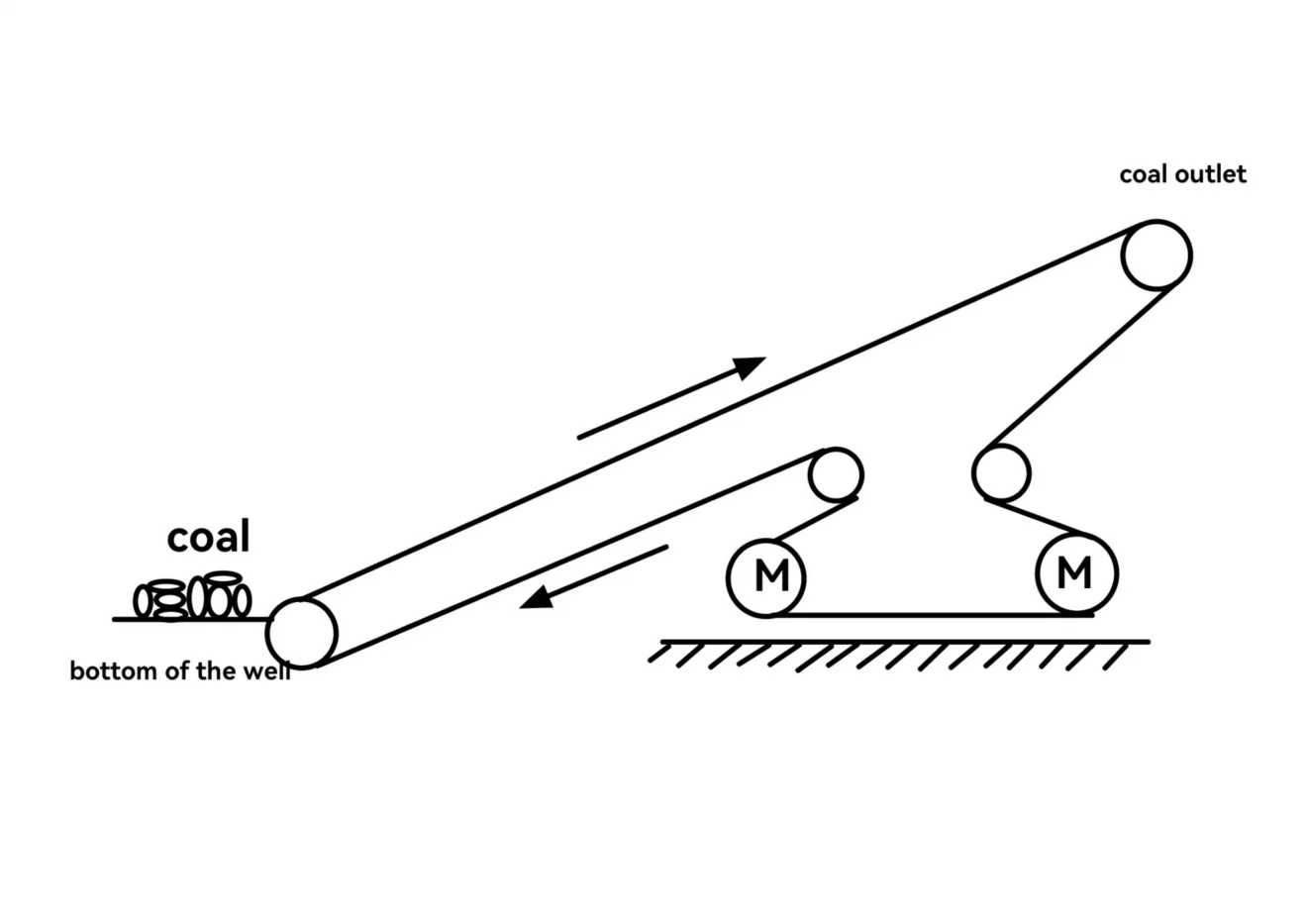

Coal washing plants rely heavily on belt conveyors for continuous material transportation. However, traditional belt conveyor systems typically use direct-on-line (DOL) or fixed-speed motor control, resulting in multiple operational challenges. These include excessive energy consumption, frequent mechanical failures due to abrupt starts and stops, and poor adaptability to varying material loads. Additionally, the lack of precise speed control often causes misalignment, belt slippage, and wear-and-tear on mechanical components. These issues can lead to substantial maintenance costs and unplanned downtime. USFULL, a leading VFD manufacturer in China, addresses these challenges by integrating advanced variable frequency drive (VFD) solutions into coal washing plant operations.

How Do USFULL Variable Frequency Drives Improve Energy Efficiency and Reduce Operational Costs?

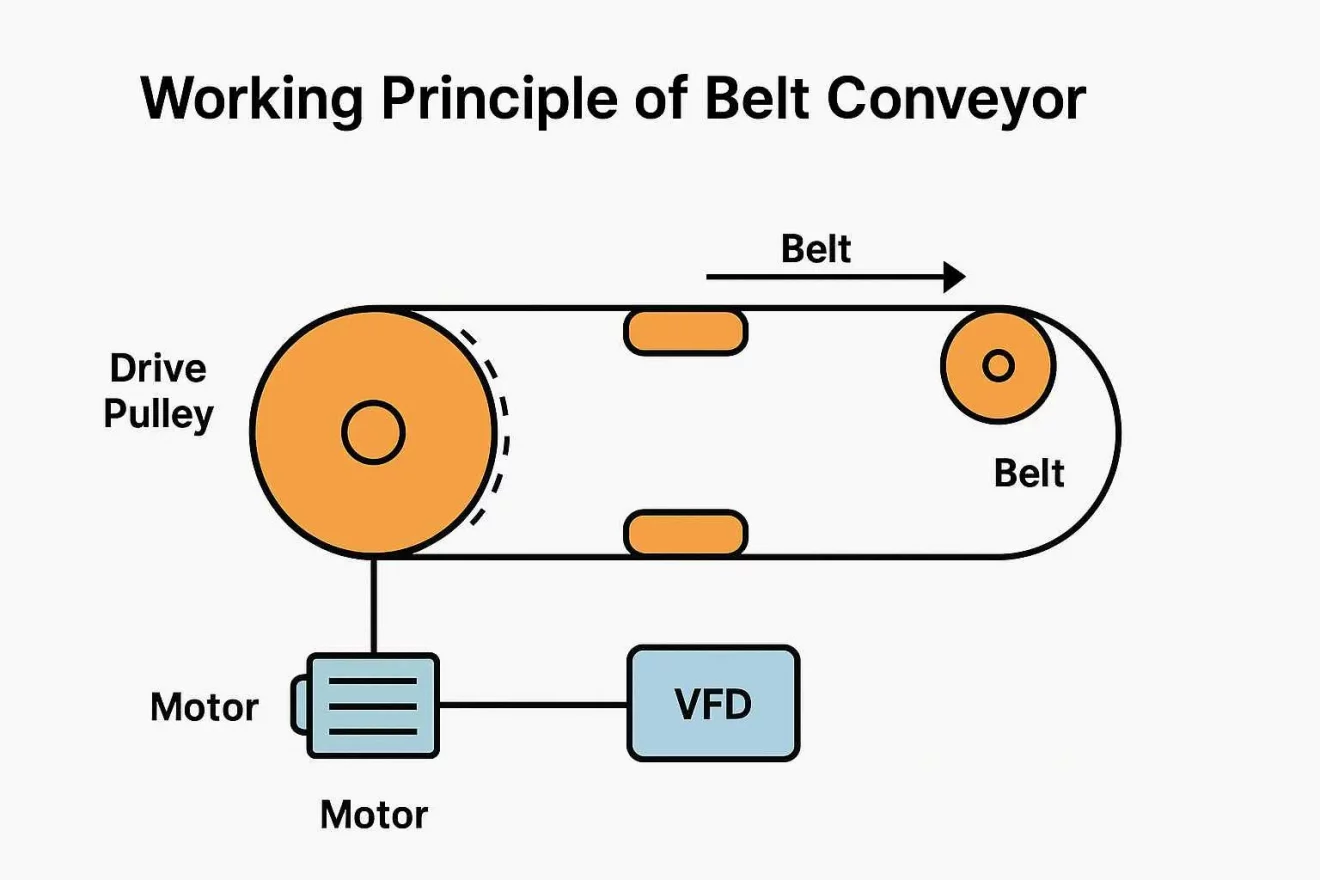

USFULL variable frequency inverters (VFDs) enhance energy efficiency by precisely controlling the speed and torque of the belt conveyor motor. Instead of running at a constant speed, the frequency inverter adjusts motor output based on real-time load demands. This optimization reduces energy consumption, minimizes mechanical stress, and extends equipment lifespan. Moreover, USFULL’s VFDs offer regenerative braking features, recovering excess energy during deceleration and feeding it back into the power grid. This not only cuts energy costs but also aligns with global sustainability goals. By switching to USFULL’s VFDs, coal washing plants can achieve up to 30% energy savings and significantly lower maintenance expenses.

What Advanced Control Features Do USFULL VFDs Offer for Belt Conveyors?

USFULL Variable Speed Drives (VSDs) are engineered with cutting-edge features tailored to coal washing plant needs. Key functionalities include:

- Soft start and stop: Reducing mechanical stress and extending belt lifespan.

- Master-slave synchronization: Ensuring uniform motor operation across multiple drives to prevent belt slippage and material misalignment.

- Adaptive load control: Automatically adjusting motor speed based on conveyor load, enhancing efficiency and throughput.

- Multiple control methods: Including digital, analog, remote communication (e.g., Modbus, Profibus), and programmable logic controls for seamless system integration.

- High torque at low frequencies: Providing stable operation even under heavy load and starting conditions.

These features make USFULL VFDs an ideal solution for coal washing plants aiming to improve reliability and performance.

How Does USFULL Design Solutions for Coal Washing Plant Conveyor Systems?

USFULL designs tailored variable frequency drive solutions for coal washing plant belt conveyor systems, addressing the specific operational challenges faced by customers. For instance, a typical design might involve two 380V/160KW motors driving a conveyor system. In this scenario, USFULL recommends two high-performance FU9000D series variable frequency inverters configured in a master-slave setup. This configuration ensures both motors operate in perfect synchronization, effectively eliminating current imbalance and speed mismatch issues common in traditional setups.

Key aspects of the design include:

- Master-slave control: The master VFD controls speed, while the slave VFD can operate in torque or speed-following mode to maintain balance and prevent belt misalignment.

- Flexible speed and torque control: The system dynamically adjusts to load changes, ensuring stable operation even during heavy material flow or restart conditions.

- Robust overload handling: USFULL VFDs deliver high torque at low frequencies and provide reliable performance under full load and high-demand conditions.

- Intelligent communication: Integration with SCADA, PLCs, and other control systems via Modbus or Profibus ensures real-time monitoring, automated adjustments, and predictive maintenance.

This thoughtful design not only reduces energy consumption and maintenance costs but also improves overall plant efficiency and extends equipment life. As a leading VFD manufacturer in China, USFULL’s expertise guarantees solutions that meet the highest standards of performance and reliability.

Why Is USFULL a Trusted VFD Supplier for Coal Washing Plants Worldwide?

As a premier VFD manufacturer and supplier in China, USFULL brings extensive experience, cutting-edge technology, and a commitment to quality. Established in 2005, USFULL has over 40 dedicated R&D specialists and a global presence in over 90 countries. Our production facilities ensure stringent quality control, certified with ISO9001, CE, IEC, TUV, and INMETRO standards. Our frequency inverters are designed with user-friendly interfaces, easy parameter setting, and robust fault protection mechanisms to ensure reliability in harsh industrial environments. Whether you need customized solutions or standard models, USFULL’s expertise as a VFD manufacturer guarantees superior performance and excellent customer service.

What Are the Tangible Results of Using USFULL VFDs in Coal Washing Plants?

Real-world applications of USFULL VFDs in coal washing plant belt conveyors have delivered remarkable results:

- Reduced downtime: With soft start/stop capabilities and torque balancing, equipment failures are minimized, and unplanned maintenance is significantly reduced.

- Optimized energy usage: VFD-controlled motors only use the energy required, resulting in 20-30% lower energy consumption.

- Improved operational safety: Adaptive load control and synchronized operation prevent belt overloading and reduce the risk of mechanical breakdowns.

- Extended equipment lifespan: Lower mechanical stress reduces wear on belts, couplings, and motors, lowering replacement costs.

- Scalability and flexibility: Modular design allows for easy system expansion and integration with existing control systems.

These benefits translate into higher production efficiency and greater profitability for coal washing plants using USFULL VFD solutions.

How do USFULL VFDs enhance system integration and automation?

USFULL’s variable frequency drives support advanced automation features essential for modern coal washing operations. Our inverter VFDs offer seamless integration with SCADA systems, programmable logic controllers (PLCs), and various communication protocols. This enables real-time monitoring, predictive maintenance, and adaptive control based on material flow rates and operational conditions. The modular software architecture allows for customizable control logic, multi-speed programming, and fault diagnostics. As a result, coal washing plants can achieve higher levels of automation, reducing human error and ensuring consistent material throughput. This integration is key to building future-ready, energy-efficient facilities.

Why Choose USFULL as Your VFD Manufacturer and Supplier?

Choosing USFULL means partnering with a trusted VFD supplier offering premium-quality products, exceptional service, and global reach. Our extensive experience in providing tailored VFD solutions for industrial applications—including coal washing, water supply, and manufacturing—positions us as a leader in the field. We offer a comprehensive product portfolio ranging from low-voltage to high-power VFDs, all customizable with client logos and specifications. With an extensive after-sales service network and technical support, USFULL ensures smooth implementation and long-term performance. Trust USFULL as your variable frequency drive partner for reliable, high-performance solutions in coal washing plant operations.