When using VFDs in industrial systems, connecting a resistive load incorrectly can cause overheating, system failure, or even fire—fortunately, there are safe and effective solutions.

Yes, a resistive load can be connected to a variable frequency drive, but it must be engineered properly to avoid overcurrent, thermal issues, and VFD malfunction.

Keep reading to understand the technical considerations and best practices to prevent costly damage to your VFD system.

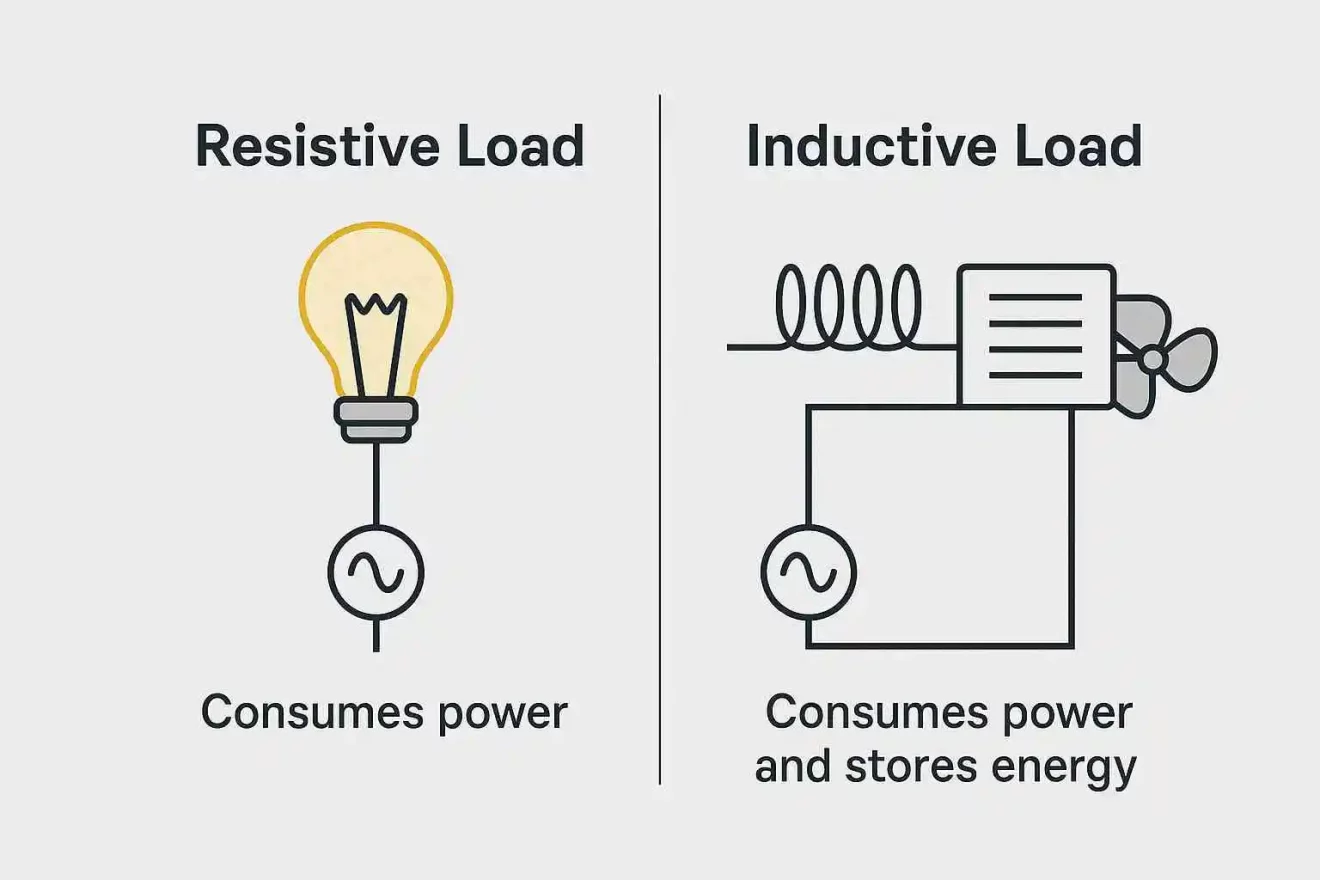

What Is a Resistive Load, and How Does It Differ from an Inductive Load?

Resistive loads, such as electric heaters or incandescent bulbs, convert electrical energy directly into heat without inducing magnetic fields. This contrasts with inductive loads like motors, which involve magnetic fields and reactive power. Most variable frequency drives (VFDs) are designed for inductive loads. When a resistive load is connected to a frequency inverter, it may draw higher instantaneous current, leading to stress on VFD components. Understanding this difference is critical when integrating resistive loads into a variable speed drive (VSD) system.

Can a VFD Safely Operate a Resistive Load?

In certain scenarios, a VFD can operate a resistive load safely—provided the load is well within the VFD’s rated voltage, current, and thermal capacity. The main challenge lies in the current profile: resistive loads tend to demand constant and high current, especially during startup. Since inverter VFDs are built to manage variable current from motor torque adjustments, a constant resistive draw may result in overcurrent trips or thermal derating. Additionally, if the VFD supplier did not design the drive for such applications, component lifespan may shorten.

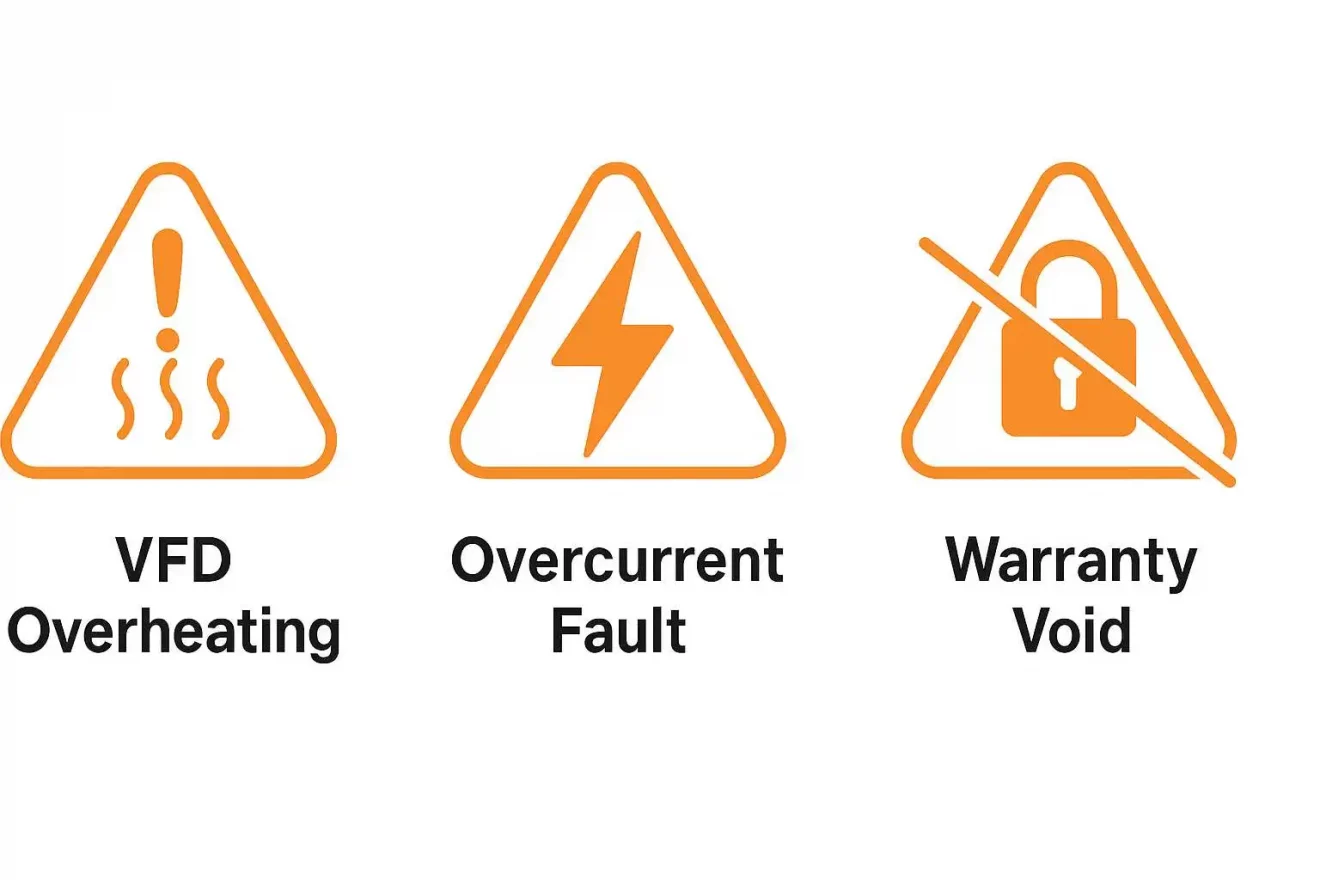

What Are the Risks of Connecting Resistive Loads to VFDs?

The primary risks include:

Overheating: Continuous operation of resistive elements increases the thermal load on the frequency inverter, which may lack adequate cooling.

Overcurrent Damage: If the resistive load exceeds the VFD’s output capacity, it may trigger faults or burn out the output stage.

Reduced Efficiency: VFDs modulate frequency and voltage for inductive optimization. With resistive loads, this modulation may not be energy-efficient.

Certification Issues: Many VFD manufacturers in China provide compliance certificates based on motor loads. Using resistive loads may void warranty or violate usage guidelines.

To avoid these risks, always check with the VFD manufacturer about supported load types.

Are There Applications Where This Setup Makes Sense?

Yes. In some industries, resistive loads are intentionally connected to VFDs for precise heating control. For example:

Industrial resistive heating elements used in drying or curing processes

Temperature-controlled ovens where heating rates are managed via variable frequency inverters

Certain test benches where adjustable AC output is required for resistive simulations

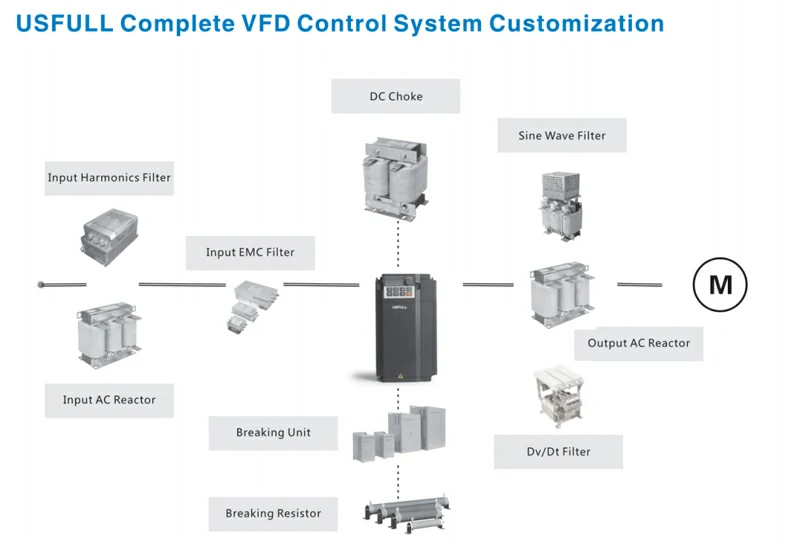

In such cases, a properly rated VFD with robust thermal management and output filters can manage resistive loads effectively. Partnering with an experienced VFD supplier ensures the system is tailored for your use case.

What Precautions Should You Take When Using VFDs with Resistive Loads?

To ensure safe and reliable operation:

Power Matching: Ensure the load’s wattage does not exceed the VFD’s rated output.

Cooling Considerations: Install external fans or heatsinks to manage the VFD’s thermal load.

Short Circuit Protection: Use fuses or circuit breakers between the VFD and resistive element.

Bypass Options: In some cases, it may be better to bypass the VFD after startup and feed the resistive load directly with AC power.

Manufacturer Consultation: Work with a qualified VFD manufacturer in China like USFULL to verify application-specific suitability.

What Type of VFD Should You Use for Resistive Loads?

Standard motor-grade VFDs may not be suitable for high-power or continuous resistive applications. Look for:

Heavy-duty VFDs with overload protection

Units with advanced thermal control algorithms

Frequency inverters with configurable output voltage and ramp-up settings

Custom-built variable frequency drive systems from trusted VFD manufacturers

Some VFD suppliers offer drives specially designed for resistive applications. This ensures optimized control, protection, and compliance with industrial standards.

What Does the Manufacturer Recommend?

At USFULL, a trusted VFD manufacturer in China, we recommend that customers avoid connecting standard VFDs to resistive loads without a technical consultation. Our variable frequency drives are optimized for motor applications but can be customized for alternative uses upon request.

Our engineering team can:

Assess your resistive load profile

Recommend suitable variable frequency inverter models

Configure the VFD for high-current resistive performance

Provide certification and thermal design support

We always encourage clients to contact our team early in the design process to avoid common errors.

Final Thoughts: Should You Connect Resistive Loads to a VFD?

In summary, it is technically feasible to connect a resistive load to a variable frequency drive, but only under carefully controlled conditions. Whether you’re using a VSD, inverter VFD, or any other type of frequency inverter, the key is to evaluate the electrical characteristics, thermal profile, and load requirements in detail.

Consulting with a qualified VFD supplier like USFULL ensures:

The drive is correctly rated

Risk of damage is minimized

Efficiency and safety are maximized

For custom support, contact our variable frequency drive experts to discuss your application and find the right solution.