When the variable frequency drive is set incorrectly, motors fail to start smoothly, causing high inrush current, overheating, and equipment shutdowns. Correctly setting the starting frequency ensures safe motor acceleration and stable system operation.

The appropriate starting frequency for a variable frequency drive (VFD) typically ranges from 0.5 Hz to 15 Hz, depending on the load type and system conditions. Light-load applications start smoothly from 0 Hz, while high-torque or high-pressure systems require higher starting frequencies to overcome static friction and ensure proper torque output.

Finding the right starting frequency is both an art and a science. Let’s explore how it works and how professionals and VFD manufacturers determine this critical setting.

How to Determine the Starting Frequency of a Variable Frequency Drive?

The starting frequency of a variable frequency drive (VFD) defines the initial output frequency when the motor begins to accelerate from rest. This parameter is crucial because it directly affects the motor’s starting torque and current.

In general, most electric motors can start from 0 Hz, but not all load types allow that. If the connected load has high inertia, friction, or back pressure (as in pumps or compressors), the motor may struggle to start at very low frequencies. In these cases, the VFD’s starting frequency should be increased to ensure enough electromagnetic torque is generated to overcome static resistance.

As a guideline:

Light loads (fans, centrifugal pumps): 0 – 5 Hz

Constant-torque loads (conveyors, compressors): 2 – 10 Hz

High-inertia or pressurized systems: 10 – 15 Hz

Selecting the optimal starting frequency depends on observing current peaks and mechanical vibration during startup. Most modern variable frequency drive manufacturers recommend starting at a low frequency and gradually adjusting upward until smooth acceleration is achieved without overcurrent trips.

Can the VFD Start Directly from a Specific Frequency?

Yes, a VFD or frequency inverter can start directly from a preset frequency, but this feature should be used carefully. Normally, drives accelerate gradually from 0 Hz, but in certain systems, starting directly from a specific frequency is necessary.

For instance, multi-pump water supply systems often maintain residual pressure in the pipes. If the inverter VFD starts from 0 Hz, the pump may not overcome the back pressure, resulting in motor stalling. By setting a starting frequency of 10 – 20 Hz, the VFD immediately provides sufficient torque to overcome system resistance.

Similarly, variable speed drives (VSDs) controlling heavy mechanical loads such as crushers or agitators may require an elevated starting frequency to overcome static friction. However, high starting frequencies increase current peaks and may stress the power supply or drive components.

The best practice is to follow the motor manufacturer’s specifications and the VFD manufacturer’s recommendations to find the proper balance between torque, current, and system safety.

How Starting Frequency Works

To understand how starting frequency affects performance, it’s important to consider how a variable frequency drive controls the motor.

A VFD adjusts the output voltage and frequency supplied to the motor. At 0 Hz, the motor’s magnetic field is weak, resulting in low starting torque. As the frequency increases, the magnetic flux strengthens, producing more torque. However, beyond a certain frequency, the effects of eddy currents, magnetic saturation, and skin effect reduce efficiency and torque.

Thus, the starting frequency determines when the motor first receives sufficient voltage-to-frequency (V/f) ratio to generate the torque required to rotate. If this setting is too low, the motor will vibrate or fail to start. If it is too high, the motor will draw excessive current, causing thermal stress and possible overcurrent trips.

Modern variable frequency inverter systems feature torque boost functions that automatically adjust voltage to provide extra torque during startup, allowing smoother acceleration even at lower frequencies.

Method for Setting the Starting Frequency of a Variable Frequency Drive

Setting the starting frequency typically involves programming the VFD parameters through its control panel or software. Though model codes vary by VFD manufacturer, most drives use a parameter labeled something like F0-03 or P1.06 for “starting frequency.”

Here’s a step-by-step approach used by professional technicians and VFD suppliers:

Identify the load type: Determine whether it is light, constant-torque, or high-inertia.

Start from a low frequency: Begin with 2 Hz and observe the motor’s response.

Monitor current and torque: If the motor struggles to turn, incrementally increase the starting frequency by 1 Hz until smooth operation is achieved.

Enable torque boost: Most variable frequency drives have an automatic torque-boost function to assist low-frequency startups.

Set acceleration time: Adjust ramp-up time to prevent sudden current spikes.

Experienced technicians also rely on data from VFD manufacturers in China like USFULL, who provide startup guidelines specific to each model and application type.

What Differences Will Occur in the VFD at Different Startup Frequencies?

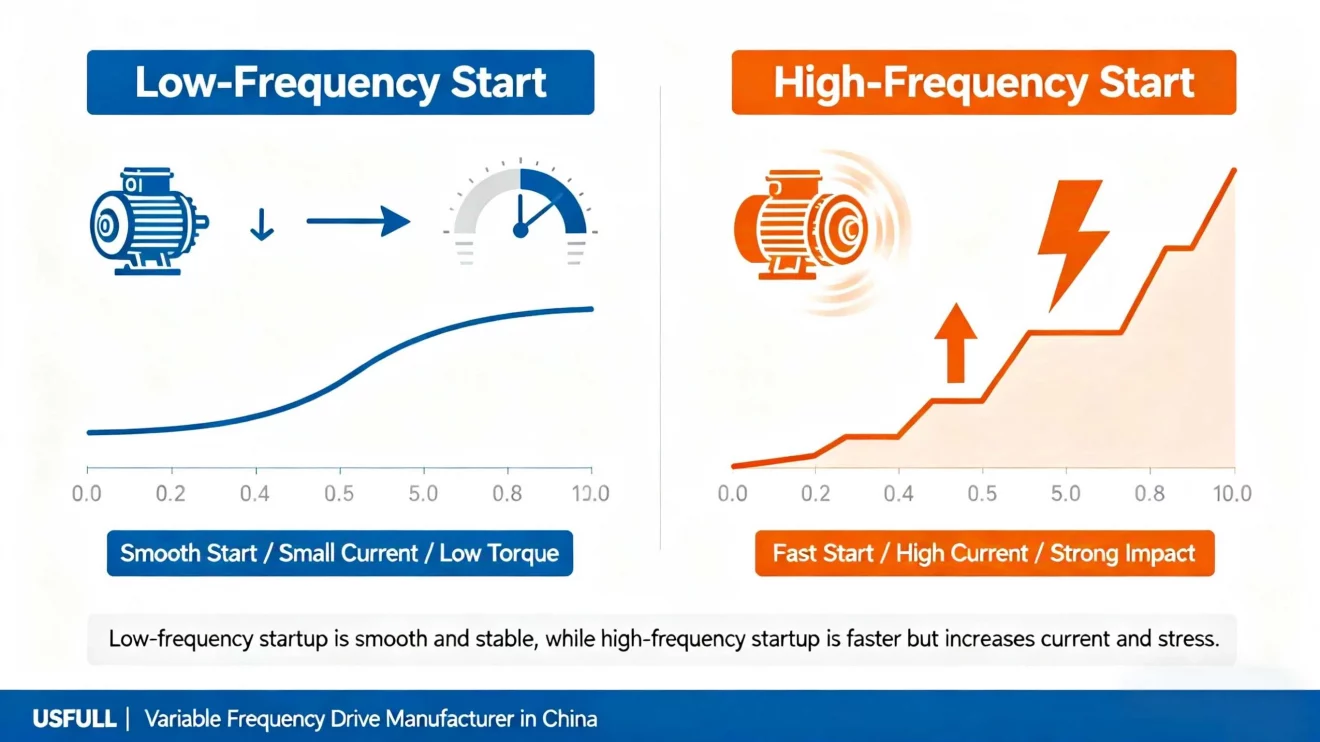

Changing the startup frequency significantly alters the electrical and mechanical behavior of the system.

Current Peak: Higher starting frequencies cause larger inrush currents because the motor quickly reaches higher torque levels. This can trigger overcurrent protection if the VFD capacity is undersized.

Torque Output: Low starting frequencies result in weaker magnetic flux and reduced torque. At optimal frequencies (around 5 – 10 Hz for most motors), torque rises efficiently. However, excessively high frequencies can reduce torque due to magnetic losses.

Dynamic Response: A higher starting frequency shortens acceleration time, leading to faster system response but higher mechanical stress.

Thermal Impact: Long periods of low-frequency operation generate more heat in the stator windings because of reduced cooling airflow, while high-frequency startups create transient heat spikes.

System Efficiency: Proper tuning of the starting frequency ensures smooth acceleration, less vibration, and higher overall efficiency of the variable speed drive (VSD) system.

In summary, each adjustment of the starting frequency shifts the balance among current, torque, and thermal conditions. The key is optimization — finding the point where the drive delivers sufficient torque without exceeding safe current or temperature limits.

Final Insights from USFULL — A Trusted VFD Manufacturer in China

Choosing an appropriate starting frequency is essential for achieving stable, efficient, and reliable performance from your variable frequency drive system. As a professional VFD manufacturer and supplier, USFULL recommends starting with low frequencies and increasing gradually based on real-world performance.

Our engineering team continuously develops intelligent variable frequency inverter solutions with features such as soft start control, automatic torque boost, and overcurrent protection — ensuring that every startup is smooth, safe, and energy-efficient.

By setting the right starting frequency, you not only protect your motor but also maximize the service life of your inverter VFD, reduce maintenance costs, and enhance your system’s operational stability.