When charging resistors or energy storage capacitors fail, the VFD may experience sudden power loss, blown rectifier bridges, or complete inverter failure. These issues can halt production, damage motors, and cause costly downtime. The solution: precise component selection and proper circuit design.

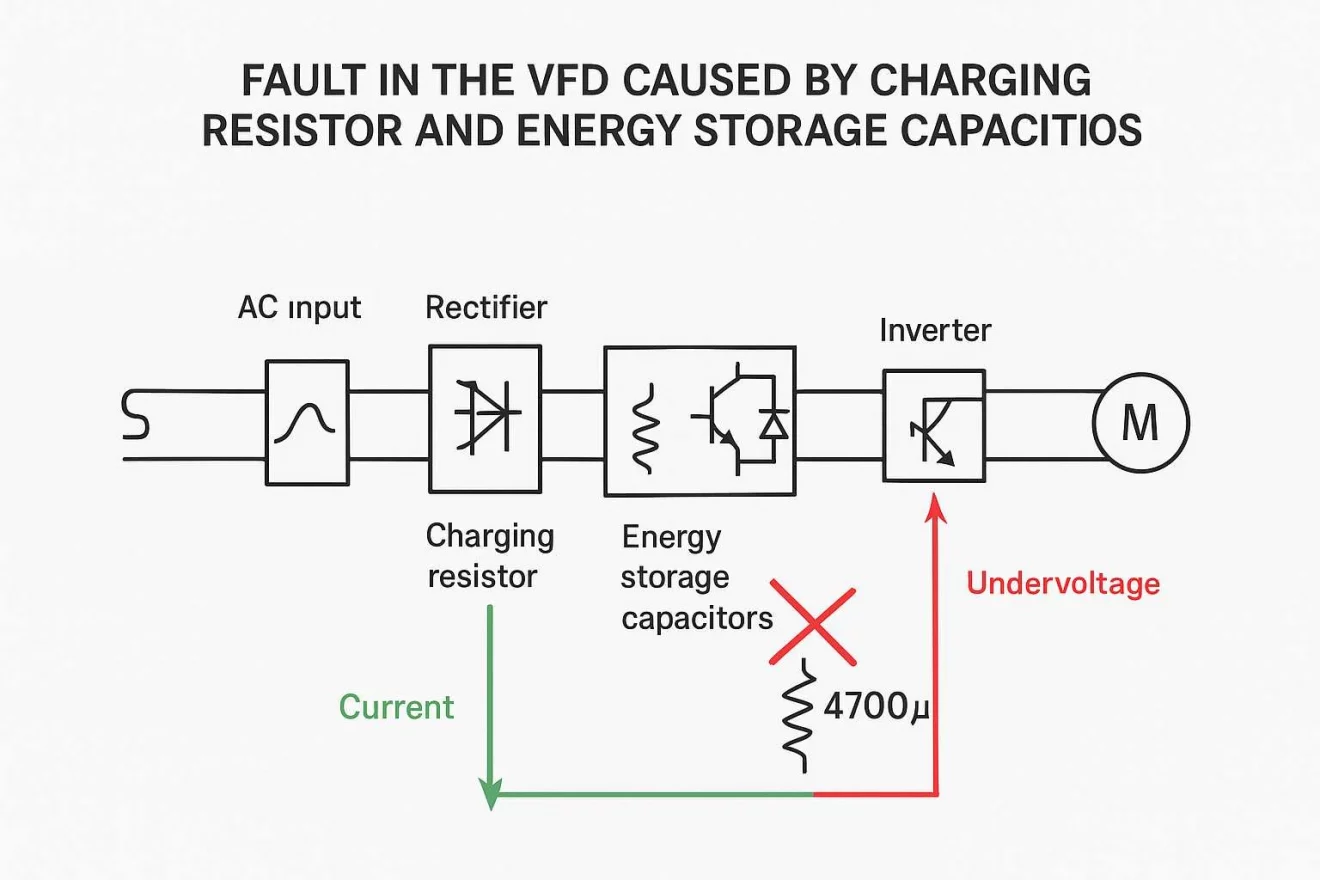

A VFD fault caused by charging resistors and energy storage capacitors occurs when the inrush current or insufficient DC energy storage disrupts the DC bus voltage stability, leading to overvoltage, undervoltage, or IGBT failure. Preventing this requires optimized resistor values and capacitor maintenance.

The key to long-term VFD reliability lies in understanding how these components work together to stabilize power flow and protect sensitive circuits.

The Crucial Role of Charging Resistors in a Variable Frequency Drive

A Variable Frequency Drive (VFD), also called a frequency inverter or Variable Speed Drive (VSD), uses a “AC–DC–AC” conversion process. When the VFD first powers on, the DC bus capacitors act like a short circuit because they are initially uncharged. This results in a massive inrush current through the rectifier.

To protect the system, a charging resistor is placed between the rectifier and capacitors. It limits the initial surge current, allowing the capacitors to charge gradually. Once the voltage reaches a safe level, a relay or thyristor bypasses the resistor to allow normal operation.

If this resistor fails or the bypass relay malfunctions, the resistor can overheat and burn, or the rectifier bridge can explode due to excessive current. Repeated power cycling, poor relay contacts, or defective control circuits are common causes.

In short, charging resistors safeguard the input rectifier stage of a frequency inverter, preventing high inrush damage and ensuring a controlled startup sequence.

How to Choose the Right Charging Resistor Value

Incorrect resistor selection is one of the most common reasons for VFD startup failure. A resistor that’s too small allows excessive current and damages the rectifier, while one that’s too large delays capacitor charging, triggering DC bus undervoltage faults.

The key is to balance current limitation and charging time. For three-phase 380V systems, the resistor should typically be between 10Ω and 300Ω, depending on the inverter power. Larger VFDs use smaller resistors because their DC capacitors require more current for charging.

For example, a 22kW inverter VFD with a 45A rated current should use a resistor small enough to allow quick charging but large enough to limit surge current. The ideal choice ensures the control board receives stable auxiliary power at around 200V DC before the relay closes.

Tip from a VFD manufacturer in China: Always verify the relay timing and resistor power rating before replacing components. A simple miscalculation can lead to repeated resistor failures or rectifier explosions.

The Importance of Energy Storage Capacitors in Frequency Inverters

In a variable frequency drive, the energy storage capacitors maintain stable DC voltage for the inverter stage. Their role is to smooth out voltage ripples and store enough energy to handle load fluctuations.

The general selection rule is ≥ 60µF per ampere of rated current. For instance, a 15kW frequency inverter rated at 30A should have at least 1,800µF of total capacitance, usually achieved with multiple high-voltage electrolytic capacitors in series or parallel.

When capacitors age, their capacity decreases and internal resistance increases. This results in DC bus voltage fluctuations, reduced load capability, and increased risk of IGBT failure. In severe cases, the inverter module may fail catastrophically because the control circuit cannot react quickly enough to sudden voltage dips or spikes.

Aging capacitors are one of the hidden killers in long-running VFDs. Even when they test “within range” using a capacitance meter, real-world operation can expose performance degradation due to heat, ripple current, or oxidation at the terminals.

Regular capacitor inspection and replacement every 3–5 years is a critical maintenance step recommended by experienced VFD suppliers and variable frequency drive manufacturers worldwide.

The Chain Reaction: How Component Degradation Leads to Total VFD Failure

When a charging resistor burns out, the inverter cannot precharge its capacitors properly, causing repeated start-up failures or blown rectifiers.

When capacitors lose capacity, the DC bus becomes unstable, leading to overcurrent or overvoltage conditions that destroy IGBT modules.

This domino effect can result in:

Instantaneous IGBT breakdown under high-frequency resonance conditions;

Bus undervoltage faults during acceleration or heavy load;

Overcurrent tripping and complete inverter shutdown.

These problems are especially common in older VFDs operating in high-temperature or dusty environments. Preventive inspection of resistors, relays, and capacitors can dramatically reduce repair costs and extend equipment lifespan.

Diagnostic Tips from a VFD Manufacturer in China

As a leading variable frequency drive manufacturer, USFULL recommends the following steps when diagnosing power circuit faults:

Measure DC bus voltage at startup — if voltage drops quickly or fails to rise smoothly, suspect the charging resistor or relay.

Check capacitor ESR (Equivalent Series Resistance) using an LCR meter — high ESR indicates aging or internal corrosion.

Observe resistor temperature — excessive heat suggests the relay is not bypassing correctly.

Inspect for frequent start/stop operations — excessive cycling shortens both resistor and capacitor life.

By applying these methods, maintenance engineers can accurately identify the root cause rather than repeatedly replacing components.

The Hidden Details Behind a Reliable VFD

The next time a Variable Speed Drive (VSD) fails unexpectedly, don’t overlook the small components.

Charging resistors and energy storage capacitors may seem insignificant, but they form the foundation of the inverter’s reliability.

Through proper component selection, periodic maintenance, and collaboration with an experienced VFD supplier, you can prevent costly downtime, protect your equipment, and extend the lifespan of your entire system.

Choose a trusted VFD manufacturer like USFULL — where quality engineering meets long-term reliability.