Overcurrent mis-trips waste time and money, while wrong selection risks fire and equipment loss. Correct breaker curves protect systems safely.

A miniature circuit breaker (MCB) protection curve indicates how fast the device trips at different current multiples. Selecting the right curve prevents nuisance tripping, ensures overload protection, and matches circuit breakers with specific loads.

Let’s dive deeper into how to choose the correct protection curve.

What Is a Protection Curve in Circuit Breakers?

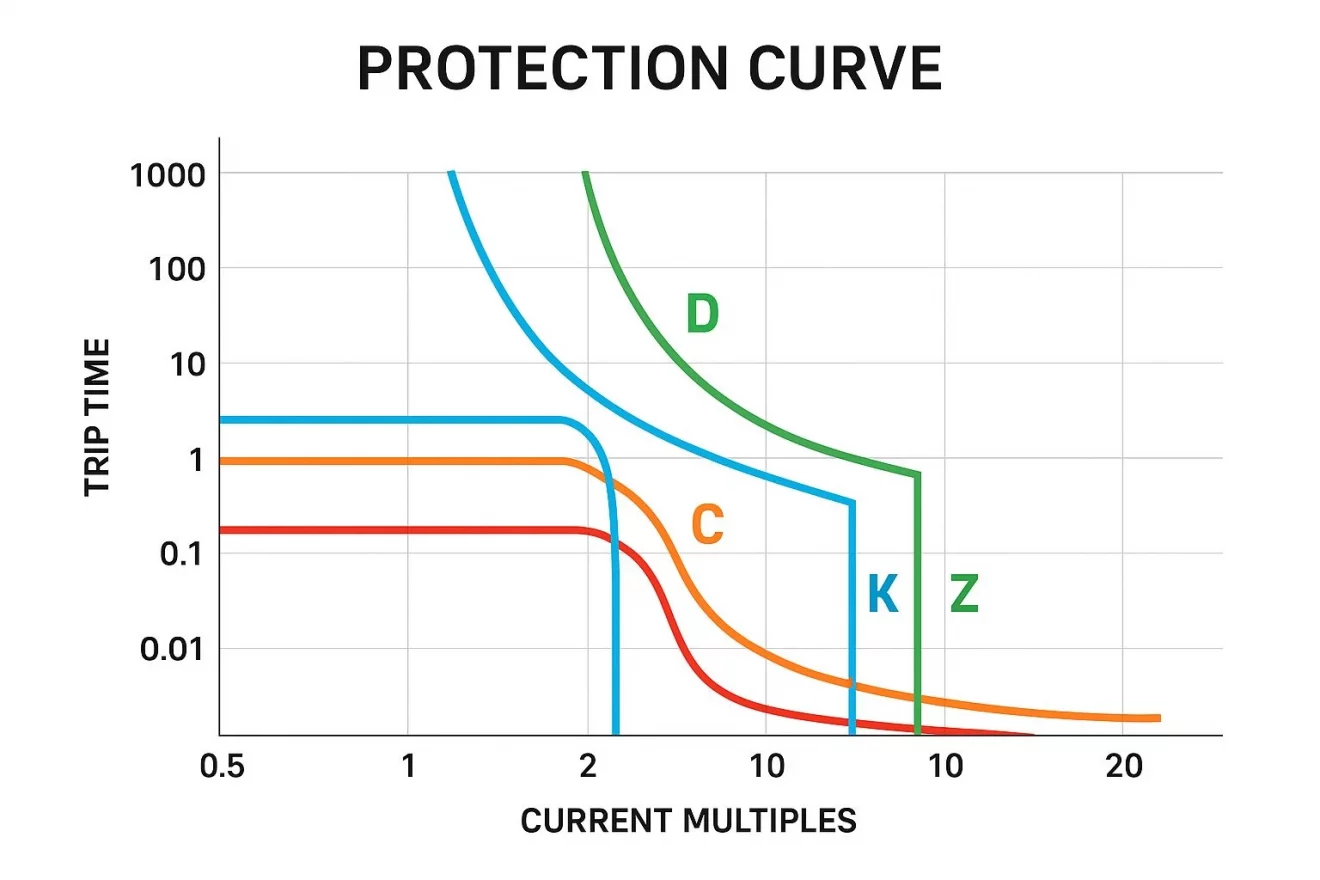

A protection curve is the characteristic trip curve of a miniature circuit breaker. It shows the relationship between current multiples and the time required to trip. This is not an immediate disconnection—it is a carefully designed delay that balances safety with operational needs.

For example, when the circuit reaches 1.13 times the rated current (In), the breaker circuit should not trip within one hour. At 1.45 In, however, the breaker must trip within one hour, preventing prolonged overloading. At 2.55 In, trip time must fall within minutes.

Understanding protection curves is critical for buyers sourcing from a Fabricante de disyuntores en China, where product variety and labeling can confuse international customers. The right interpretation ensures correct application, avoiding costly mistakes.

Thermal vs. Magnetic Trip Mechanisms

Miniature circuit breakers include two tripping mechanisms: thermal trip and magnetic trip.

Thermal Trip: This uses a bimetal strip that bends with heat. It is intentionally slow, designed to protect against long-term overload. Because thermal elements react to heat, ambient temperature changes can influence sensitivity. A hot enclosure may cause the MCB to trip earlier than expected.

Magnetic Trip: This relies on an electromagnetic coil that reacts instantly, tripping within milliseconds when short-circuit current flows. It is designed specifically for fault currents that can destroy cables and equipment.

How Does Temperature Affect Breaker Curves?

Temperature is often overlooked when selecting an MCB. The standard assumes 30 °C, but real-world installations—especially in solar applications—can exceed 40 °C inside enclosures.

In high temperatures, the bimetal strip heats faster, meaning the breaker trips at lower currents. If the average temperature is 35 °C or more, nuisance tripping may occur. Solutions include:

Increasing the rated current by one step,

Choosing adjustable thermal trip disyuntores,

Improving enclosure ventilation.

This consideration is crucial when installing Circuit Breakers in compact combiner boxes exposed to direct sunlight.

What Do the B, C, D, K, Z, and DC Curves Mean?

The letter on a breaker indicates the instantaneous magnetic trip range. Different loads require different sensitivity:

B Curve (3–5 In): For residential lighting, resistive loads, and small appliances.

C Curve (5–10 In): For air conditioners, pumps, and small motors.

D Curve (10–20 In): For transformers, UPS, or large industrial motors with high inrush current.

K Curve (8–12 In): For industrial machinery with frequent starts.

Z Curve (2–3 In): For highly sensitive electronics like PLCs or precision control.

DC Curve: Designed specifically for solar, battery storage, and other direct current systems. These breaker DC devices use arc-extinguishing chambers tailored for DC currents, which do not naturally pass zero like AC.

A professional Circuit Breaker supplier will guide customers toward the right curve based on application. Using the wrong curve leads to either nuisance tripping or dangerous failure to disconnect.

Why Testing Load Starting Current Is Essential

Every load behaves differently at startup. Motors, compressors, and even LED lighting can draw several times their rated current in the first seconds of operation. If an MCB with a B curve is selected for such loads, the breaker may trip instantly.

Accurate load measurement ensures the correct curve is chosen. For example, water pump systems paired with Solar Disyuntores de CC usually need a C or D curve to handle motor startup. Without this matching, the breaker circuit becomes a bottleneck, cutting power during normal operation and frustrating end users.

This is why international buyers sourcing from a Circuit Breaker manufacturer in China often request sample testing before bulk orders. The right supplier should provide load simulation reports to guarantee compatibility.

Why Minimum Short-Circuit Current Matters

Beyond startup current, engineers must also check the minimum short-circuit current on the line. If the short-circuit current is lower than the trip curve’s lower threshold, the breaker may fail to operate.

Industry practice requires that the minimum short-circuit current be at least 1.25 times the lower limit of the curve. For example, if using a D curve with a lower threshold of 10 In, the minimum fault current must exceed 12.5 In. Otherwise, the breaker circuit will not trip under fault, leaving equipment exposed.

This calculation is especially important for remote solar or DC systems, where impedance may reduce available fault current.

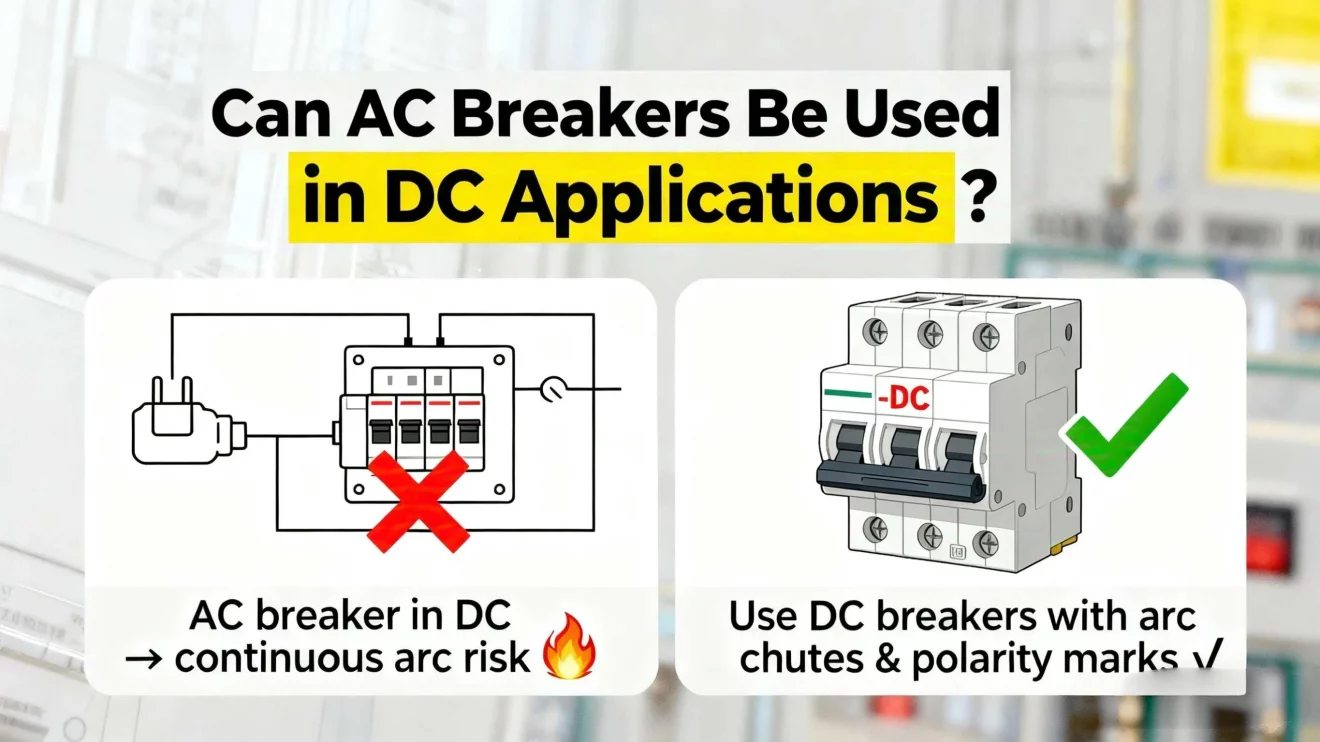

Can AC Breakers Be Used in DC Applications?

A common mistake is installing AC miniature circuit breakers in direct current systems. This is unsafe because DC arcs are more difficult to extinguish. Unlike AC, where the current crosses zero 50–60 times per second, DC maintains a continuous arc that can burn contacts.

Therefore, Disyuntores de CC solares or breaker DC models must be used in photovoltaic and storage systems. These DC circuit breakers have special arc chutes, magnetic blowouts, and polarity markings to handle DC safely.

For buyers sourcing from a Circuit Breaker manufacturer in China, always look for labels such as “-DC” and request test certificates proving DC compliance. Using the wrong product risks fire, equipment loss, and costly recalls.

Common Selection Mistakes and Their Fixes

LED lights tripping breakers: Caused by high inrush current. Solution: switch from B curve to C curve or add surge protection.

Motors tripping on startup: Curve too sensitive. Solution: use D or K curve breakers, or install soft starters.

Summer overheating in enclosures: Caused by high ambient temperature. Solution: raise In rating or improve cooling.

PV systems using AC breakers: Dangerous arc persistence. Solution: replace with DC circuit breaker certified for solar.

International customers should ensure their Circuit Breaker supplier provides full technical documentation and guides to avoid these errors.

Step-by-Step Selection Process

To simplify selection, follow this structured method:

Define the rated current (In) based on conductor size and temperature.

Identify the load type and measure startup current.

Choose the correct protection curve (B, C, D, K, Z, or DC).

Verify minimum short-circuit current meets curve requirements.

Adjust for temperature derating if necessary.

Test in real conditions before mass deployment.

By following these steps and sourcing from a reliable Fabricante de disyuntores, buyers can ensure safety, efficiency, and compliance across applications.