Inefficient VFD operation causes downtime, equipment damage, and profit loss—using reactors can prevent these costly problems.

A reactor in a variador de frecuencia (VFD) system is used to reduce harmonics, protect internal components, stabilize voltage, and extend equipment life.

Keep reading to learn when your VFD needs a reactor.

What Is a Reactor in a Variable Frequency Drive System?

A reactor is an electrical component added to a variador de frecuencia (VFD), frequency inverter, or variable speed drive (VSD) system to reduce current spikes, suppress harmonics, and stabilize voltage. It is typically installed either at the input (AC line reactor) or in the DC bus (DC link reactor) of the inverter VFD. Reactors protect sensitive power electronics inside the frequency inverter, improve power quality, and ensure stable motor operation, especially in challenging electrical environments. For businesses relying on industrial automation or pumping systems, reactors are an essential safeguard for extending VFD and motor service life.

When Should You Use a Reactor with a VFD?

You should consider adding a reactor to your variable frequency inverter when the power supply is unstable, the installation involves long cable runs, or the system operates in a harmonic-rich environment. Common scenarios include:

Long cable distances: Over 50 meters between VFD and motor, where capacitive effects increase voltage stress.

High harmonic distortion: Industrial sites with multiple frequency inverters, welders, or switching power supplies.

Large power capacity sources: Strong grids can cause harmful current surges,especially over 110 kW.

Voltage imbalance: When the imbalance exceeds 3%, motor overheating and inefficiency can occur.

Shared supply with thyristor devices: Such as soft starters, rectifiers, or reactive power compensators.

Each of these cases puts stress on both the VFD and motor, making reactors a cost-effective protective measure.

What Are the Types of Reactors Used in VFD Applications?

1. AC Input Reactor (Line Reactor)

Location: Installed at the input side of the VFD, between the power supply and the drive.

Purpose:

Reduces harmonics generated by the VFD.

Limits current surges from the supply line.

Protects the VFD from line transients, voltage spikes, and switching surges.

Improves power factor slightly by smoothing current waveform.

When used:

Weak or unstable power grid.

Systems with frequent voltage fluctuations.

To comply with harmonic mitigation standards (IEEE 519).

2. AC Output Reactor (Load Reactor)

Location: Connected at the output side of the VFD, between the drive and the motor.

Purpose:

Limits the dv/dt (voltage rise time) to protect motor insulation.

Reduces motor heating and audible noise.

Extends cable length capability between drive and motor (prevents reflected wave issues).

Minimizes bearing currents and shaft voltage.

When used:

Long motor cable runs (typically >15–20 meters).

Motors with low insulation ratings.

Sensitive motor applications requiring smoother waveforms.

3. DC Reactor (DC Link Choke)

Location: Installed in the DC bus of the VFD (between the rectifier and DC capacitors).

Purpose:

Reduces input current harmonics by smoothing the DC link current.

Limits inrush current to the DC bus capacitors.

Enhances overall VFD reliability by protecting capacitors.

Provides similar benefits to an AC input reactor but with better harmonic suppression in some cases.

When used:

Drives without built-in DC chokes (many modern VFDs already have them).

Applications with strict harmonic requirements.

Systems where capacitor protection and harmonic reduction are priorities.

Quick Comparison:

AC Input Reactor → Protects the drive from the power supply.

AC Output Reactor → Protects the motor from the drive.

DC Reactor → Protects the DC bus and improves harmonics.

How Does a Reactor Protect a Variable Frequency Drive?

Reactors serve as a protective barrier between the unstable external environment and the sensitive internal components of a VFD. They limit sudden voltage and current changes that could otherwise damage the insulated gate bipolar transistors (IGBTs) inside the inverter VFD. By reducing harmonics, reactors also prevent excessive heat generation in both the VFD and connected motors. For example, without a reactor, a voltage spike from the grid could directly stress the DC bus capacitors, leading to premature failure. By acting as a buffer, reactors help the VFD manufacturer’s recommended operating conditions remain stable, improving both reliability and lifespan.

Why Are Reactors Important for Long Cable Runs?

When a variable frequency drive is connected to a motor through long cables—over 30 meters—parasitic capacitance between conductors can cause reflected wave phenomena. These voltage reflections can significantly exceed the VFD’s rated output voltage, putting immense stress on motor windings and insulation. An output reactor in the inverter VFD circuit reduces the steepness of voltage changes (dv/dt), ensuring the motor receives a smoother waveform. This not only prevents insulation breakdown but also reduces audible motor noise. For VSD users in industries such as irrigation pumping, HVAC, and manufacturing, this means lower maintenance costs and fewer unexpected shutdowns.

Can Reactors Help Reduce Harmonic Interference?

Yes. Harmonics are unwanted higher-frequency voltages or currents that distort the ideal sinusoidal waveform. In industrial settings with many VFDs, welding machines, and UPS systems, harmonic levels can exceed safe limits, causing overheating in transformers, cables, and motors. Reactors act as a passive harmonic filter, lowering total harmonic distortion (THD) to acceptable levels. For applications with strict compliance requirements, such as hospitals, data centers, and telecom facilities, using a reactor in the VFD system ensures that sensitive equipment is not disrupted by electrical noise. This is a key reason why many VFD suppliers in China recommend reactors for critical installations.

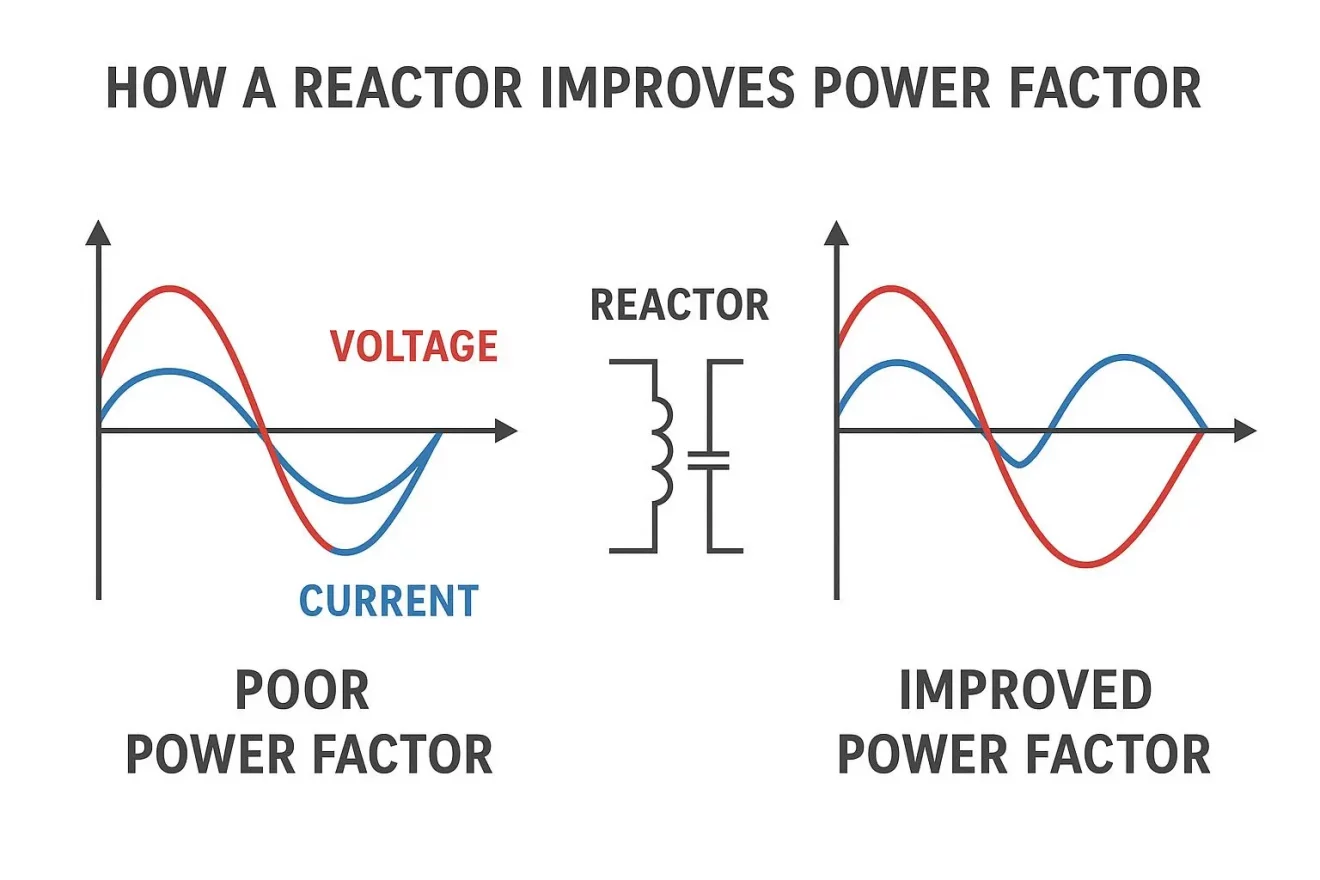

How Does a Reactor Improve Power Factor?

Power factor is a measure of how effectively electrical power is converted into useful work. A poor power factor increases utility bills and stresses the electrical network. AC line reactors can improve a VFD’s displacement power factor by reducing reactive power consumption caused by harmonics. This improvement benefits both the user—through reduced energy costs—and the utility provider—by lowering network losses. For businesses sourcing equipment from a VFD manufacturer in China, requesting a reactor-equipped solution can yield long-term operational savings and improved compliance with power quality standards.

Choosing the Right Reactor for Your VFD

Selecting the correct reactor involves matching it to the VFD’s voltage, current rating, and operating environment. Factors to consider include:

VFD capacity (kW or HP)

Motor cable length

Harmonic distortion levels

Voltage imbalance percentage

Installation environment (industrial, commercial, or sensitive electronics)

A reputable VFD supplier can help assess your system and recommend the appropriate AC line reactor, DC link reactor, or output reactor. USFULL, as an experienced variador de frecuencia manufacturer and VFD supplier, offers customized solutions to ensure maximum system protection and efficiency.