Explosive gases make ordinary VFDs risky—sparks may trigger disasters. Specialized variable frequency drives provide safe, certified solutions for these hazardous environments.

Variable frequency drives (VFDs), also known as frequency inverters or variable speed drives (VSDs), can be safely used in combustible and explosive gas environments by selecting explosion-proof models, ensuring proper installation, and maintaining strict environmental controls to prevent ignition risks.

Keep reading to discover essential guidelines for safe and efficient use of VFDs in explosive gas areas.

Why Are Ordinary Variable Frequency Drives Unsafe in Explosive Environments?

A variable frequency drive controls motor speed and efficiency, but standard models pose a severe hazard in environments containing combustible gases. During switching operations, sparks, high temperatures, or electrical arcs may occur. In coal mines, petrochemical plants, or natural gas facilities, such sparks could ignite flammable gases, leading to catastrophic explosions.

In these environments, operators cannot rely on traditional frequency inverters. Instead, specialized explosion-proof VFDs are essential. These variable frequency inverters are designed with flameproof enclosures, certified insulation systems, and protective circuits to prevent ignition sources. By using the right type of inverter VFD, companies minimize risks while maintaining energy efficiency and motor control.

How to Use an Explosion-Proof Cabinet with a VFD in Explosive Gas Environments?

In environments with explosive gases, installing a variable frequency drive (VFD) inside an explosion-proof cabinet provides an additional safety layer. To ensure reliability, the cabinet must be positioned away from direct gas leakage sources and installed on a stable foundation. All entry points should be sealed with certified flameproof cable glands, preventing any flammable gases from entering the enclosure.

When operating a frequency inverter inside such a cabinet, temperature control becomes critical. Explosion-proof cabinets should include cooling systems such as heat exchangers or positive pressure ventilation to prevent overheating of the variable speed drive (VSD). Routine inspection of sealing gaskets, grounding connections, and cabinet pressure ensures continued compliance with safety standards.

By following these measures, companies can safely operate inverter VFDs in explosive gas zones while maintaining motor efficiency, energy savings, and long-term reliability. Partnering with a trusted VFD manufacturer in China or a professional VFD supplier ensures access to certified explosion-proof solutions and expert technical support.

How to Install a VFD Safely in Hazardous Gas Environments?

Proper installation of a frequency inverter in explosive environments is as critical as selecting the right model. The first step is choosing the correct location—VFDs must be installed away from gas leakage points and in well-ventilated areas.

Wiring must follow strict safety codes. All grounding connections should be secure, and zero-line connections are strictly forbidden to avoid electrical faults. Enclosures should be sealed with flameproof or pressurized cabinets, preventing any flammable gas from reaching internal electrical components.

A trusted VFD manufacturer will provide installation guidelines and recommend protective accessories, ensuring the inverter VFD performs reliably even under dangerous conditions. By following these measures, companies extend equipment life and safeguard workers from accidents.

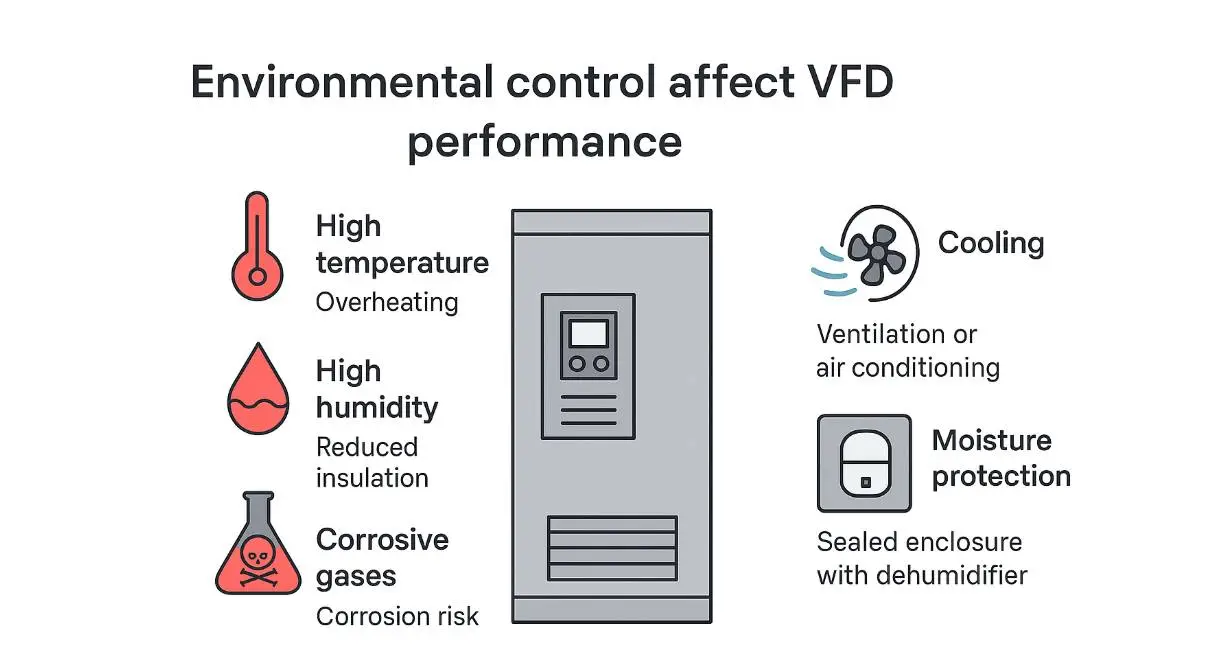

How Does Environmental Control Affect VFD Performance?

Even explosion-proof variable speed drives depend on controlled environments for safe and reliable operation. High temperatures increase the risk of overheating, while excess humidity reduces insulation performance and accelerates corrosion.

Ideally, a VFD should operate at 0–40°C with humidity levels between 40%–90%. If temperatures rise, ventilation fans or even air conditioning systems may be required. In humid conditions, sealed enclosures with dehumidifiers protect internal components.

Furthermore, corrosive gases like hydrogen sulfide or chlorine can damage metal parts and reduce drive lifespan. To avoid this, frequency inverters must be shielded against chemical exposure. By implementing strict environmental controls, companies ensure variable frequency inverters maintain efficiency and safety in explosive gas areas.

What Maintenance Practices Ensure Long-Term Safety of VFDs?

Maintenance is crucial for the continued safe use of variable frequency drives in explosive environments. Operators should routinely inspect the VFD enclosure for cracks or loose seals, ensuring it maintains its flameproof integrity.

Regular cleaning is necessary to remove dust, which can act as an ignition source if it accumulates on hot components. Electrical terminals must be tightened to prevent arcing. Cooling fans should be tested frequently to avoid overheating.

If abnormalities such as excessive vibration, unusual noise, or overheating are detected, the VFD must be shut down immediately. Partnering with an experienced VFD manufacturer in China ensures access to replacement parts, technical support, and customized service contracts to maintain operational safety.

Why Choose a Reliable VFD Manufacturer for Hazardous Applications?

The choice of supplier directly affects the safety and efficiency of operations in combustible gas environments. Not every variable frequency drive manufacturer can provide explosion-proof certification or global compliance.

Working with a professional VFD supplier ensures not only product safety but also on-time delivery, customized engineering, and reliable after-sales service. For buyers in regions such as the Middle East, Africa, or Latin America, partnering with a trusted VFD manufacturer guarantees both safety and competitiveness.