When your pump or fan system runs at fixed speed, energy waste, component wear, and lost efficiency become unavoidable. This leads to higher costs and shorter equipment life. A Variable Frequency Drive (VFD) offers precise motor speed control—solving all these pain points in one smart device.

A Variable Frequency Drive (VFD), also known as a frequency inverter or variable speed drive (VSD), controls motor speed by varying the input power frequency and voltage. This enables efficient and flexible performance for AC motors.

Don’t leave yet—understanding VFDs can dramatically improve your system’s efficiency, longevity, and cost-effectiveness.

How Do Variable Frequency Drives Change the Motor Speed?

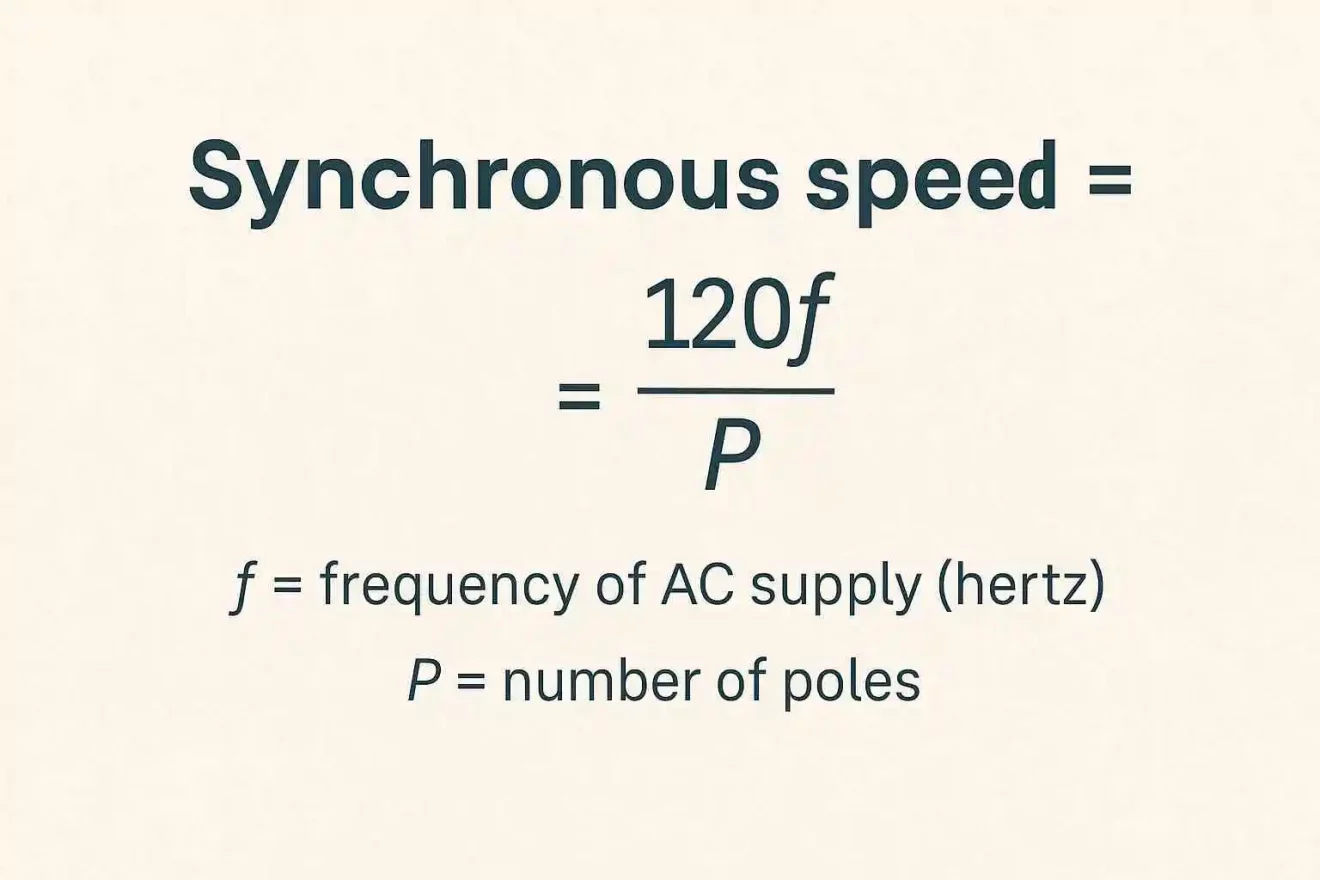

Variable Frequency Drives (VFDs) control motor speed by adjusting the frequency and voltage of the electrical power supplied to the motor. In a typical fixed-speed AC motor, the motor speed is locked to the supply frequency—commonly 50Hz or 60Hz. This fixed speed results in wasted energy during partial load operations.

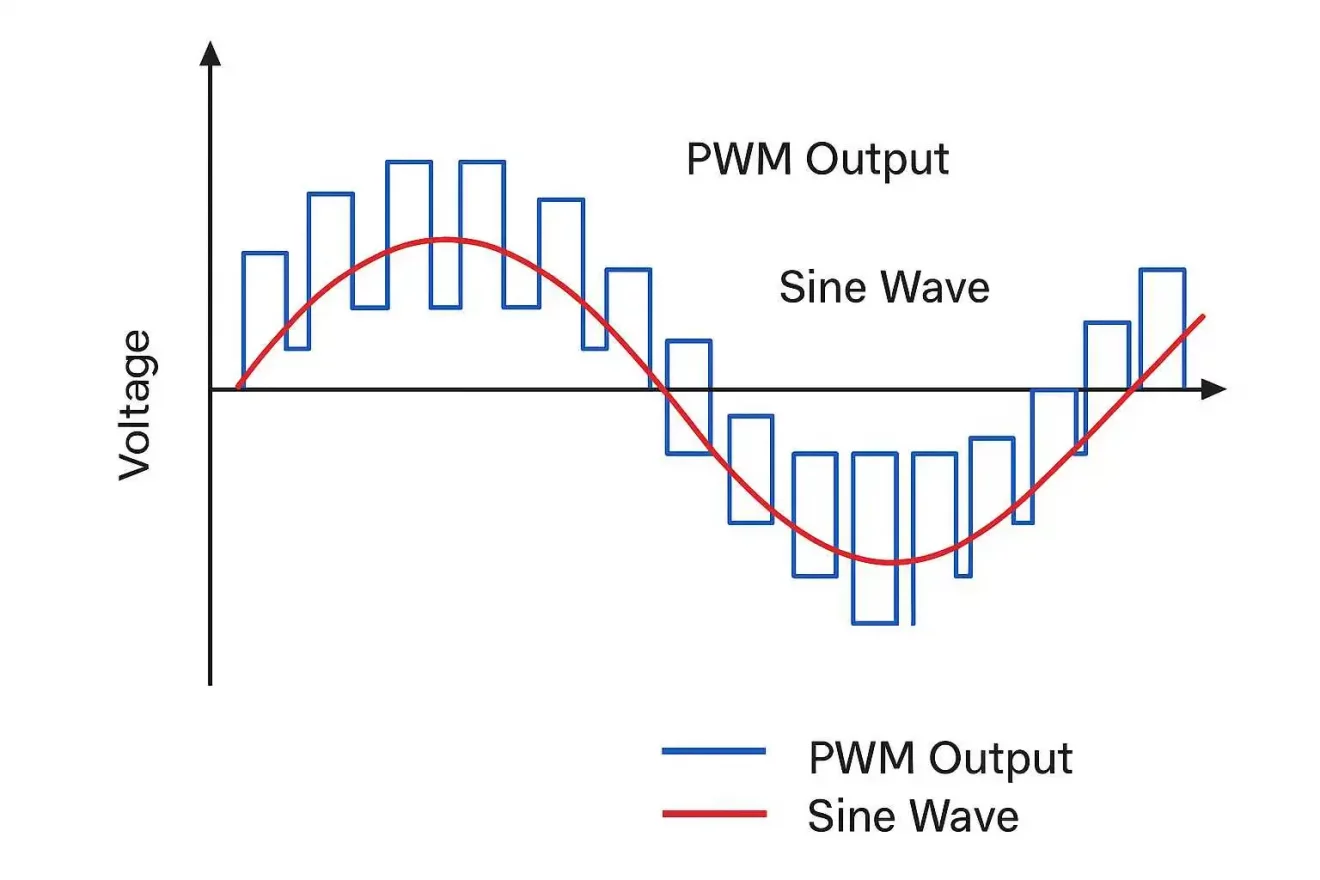

A VFD or frequency inverter changes the motor’s input frequency using a process called Pulse Width Modulation (PWM). It rapidly switches the power on and off via IGBTs (Insulated Gate Bipolar Transistors), simulating a variable-frequency sine wave. The higher the output frequency, the faster the motor speed; the lower the frequency, the slower the motor. By precisely managing these variables, VFDs offer real-time speed control that matches the load’s demand, dramatically increasing energy efficiency and operational flexibility.

What is the Basic Working Principle of VFD?

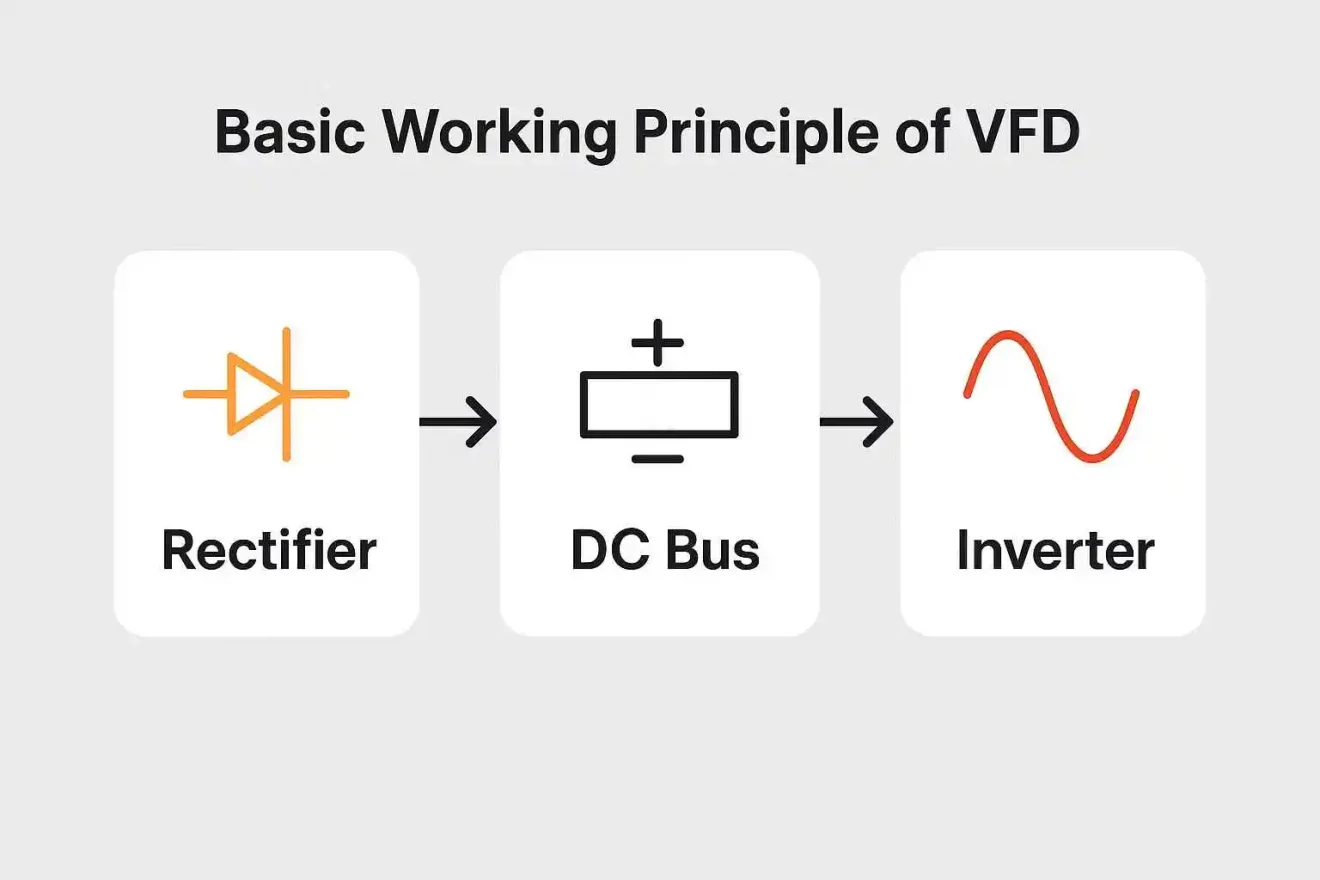

The VFD functions through three main stages: Rectifier, DC Bus, and Inverter.

- Rectifier Stage: Converts incoming AC power to DC power. This is typically done using a diode bridge that allows current to flow in one direction only.

- DC Bus (Intermediate Circuit): Stores the converted DC power temporarily using capacitors. This stage stabilizes voltage fluctuations and prepares the power for inversion.

- Inverter Stage: Converts the DC power back into AC using high-speed switching elements (IGBTs). The key here is that this AC output is no longer fixed—it’s a synthesized waveform of varying frequency and voltage, controlled by PWM (Pulse Width Modulation) algorithms.

In essence, the inverter VFD mimics a variable AC signal, allowing the motor to operate at virtually any speed within its design limits. This method is more efficient than mechanical control and significantly reduces motor wear.

How to Increase Motor Speed with VFD?

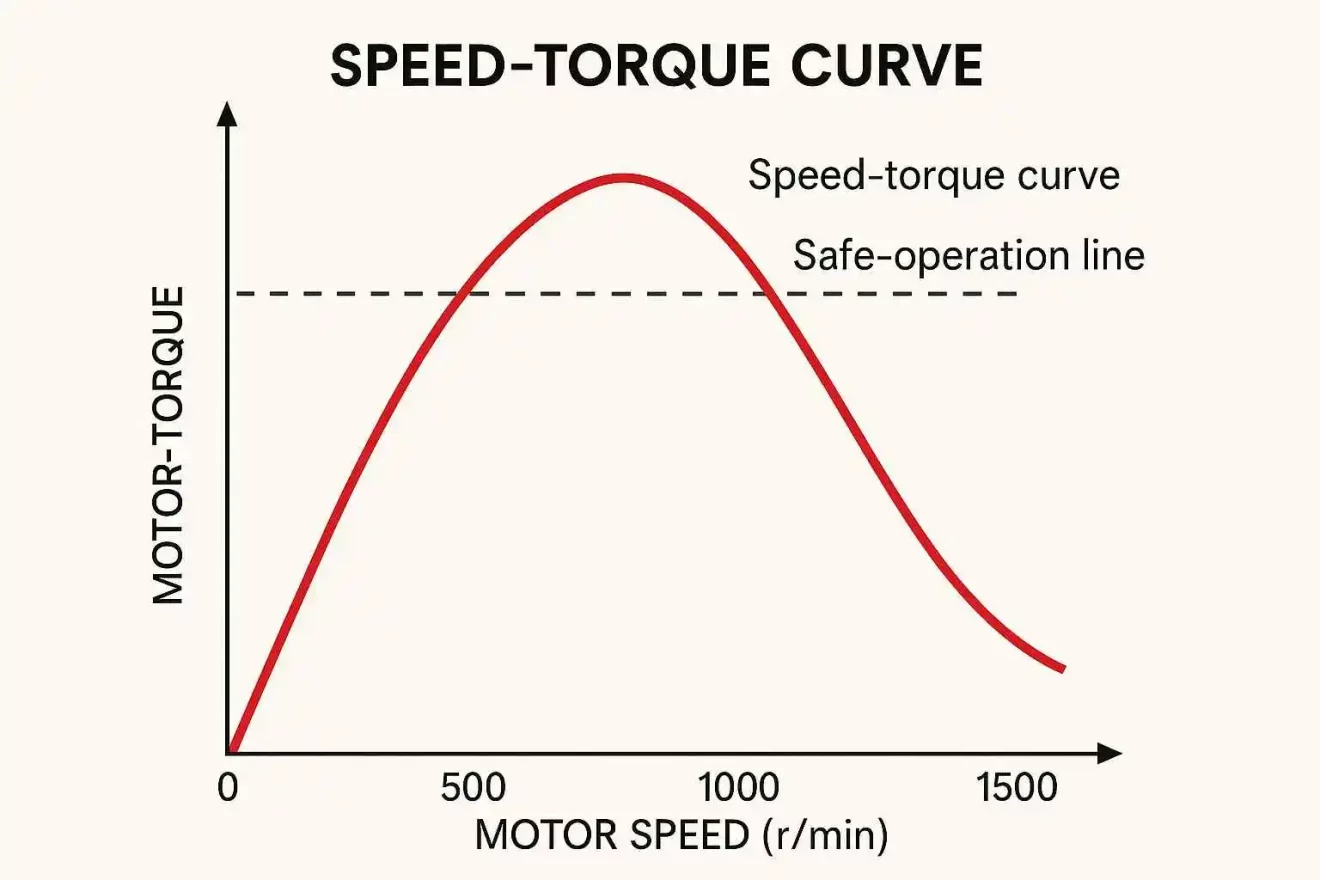

Increasing motor speed using a VFD is simple in principle but requires understanding the motor’s design limits.

- Increase Output Frequency: By raising the output frequency above the standard (e.g., from 50Hz to 60Hz or higher), a VFD (Variable Speed Drive) can boost motor speed. However, this is only advisable if the motor is rated for such operation.

- Ensure Voltage Scaling: To maintain torque when frequency increases, the voltage should also be proportionally increased. This is handled automatically in most VFDs via volts-per-hertz (V/f) control mode.

- Motor Design Consideration: Not all motors are designed to run above their nominal speed. Operating a standard motor at higher frequencies may lead to overheating, mechanical stress, and reduced lifespan. Use inverter-duty motors for best results.

- Avoid Overspeeding Ungeared Loads: In some applications like centrifugal pumps, overspeeding can cause cavitation or mechanical vibration. Always consult your motor’s manufacturer before running it above rated speed with a frequency inverter.

When used properly, increasing speed with a variable frequency inverter allows greater process flexibility and shorter cycle times without mechanical changes.

Additional Benefits of Using VFDs

Besides speed control, VFDs bring multiple performance benefits:

- Energy Savings: Especially in variable-torque loads like pumps and fans, reducing speed by 20% can save up to 50% in energy.

- Soft Start/Stop: VFDs avoid the high inrush current seen in direct-on-line starting, extending motor and mechanical component life.

- Remote and Automated Control: Advanced inverter VFDs support PLC integration, remote I/O, and sensor feedback for smart control.

- Protection Features: VFDs offer built-in protection like overload, under-voltage, phase loss, and temperature alarms.

These benefits are why VFDs have become essential in modern industrial systems worldwide—from agriculture and HVAC to manufacturing and mining.

When to Choose VFD vs Voltage Control

While VFDs dominate in 3-phase systems, voltage control with feedback is occasionally used in low-cost single-phase AC motors. This method adjusts voltage to influence speed, and uses feedback (e.g. a tachogenerator) to maintain stability.

However, this method has clear drawbacks:

Limited speed range

Risk of motor stalling at low voltage

Inaccurate speed control without sophisticated feedback

Less suitable for high-torque applications

Therefore, for most industrial, agricultural, or solar pumping applications—a variable frequency drive (VFD) or variable speed drive (VSD) is the more robust and scalable choice.

Understanding how a Variable Frequency Drive controls motor speed allows professionals like you to make informed, strategic decisions. Whether you’re optimizing energy use, protecting your motor, or increasing process flexibility, a VFD offers unmatched performance and return on investment.

At USFULL, we provide high-quality, customizable VFDs and solar pumping inverters tailored to your system’s specific needs. Whether you’re running a remote solar water system or an industrial conveyor, our variable frequency inverter solutions are backed by expert support and global certifications.