When a frequency inverter fails to control the load, operations stop, equipment risks damage, and efficiency plummets. The solution—systematic inspection and timely maintenance.

To resolve a situation where a variable frequency drive (VFD) cannot control the load, check control signals, inspect the main circuit, verify input power stability, and ensure the encoder functions properly. Addressing these core issues restores inverter control performance and prevents costly downtime.

Let’s dive deeper into the main causes and proven solutions.

Why the Frequency Inverter Fails to Control the Load

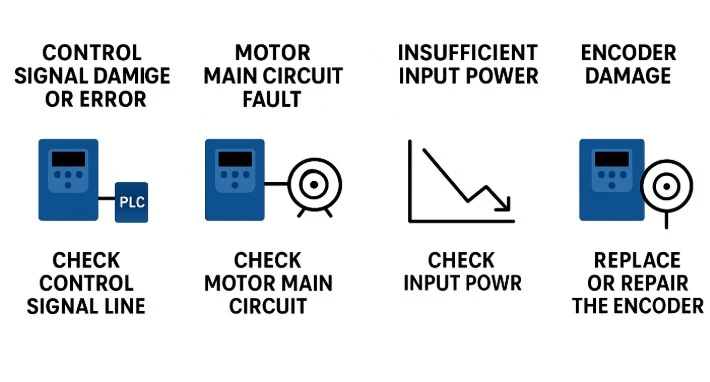

When a variable frequency drive (VFD) or variable frequency inverter cannot control the load, it’s typically due to one of four core problems: faulty control signals, damaged main circuits, insufficient input power, or encoder malfunction.

A control signal issue often stems from incorrect wiring or interference between the VFD and the control system (like a PLC). If the inverter cannot receive or interpret commands correctly, the motor will not respond as intended. Similarly, problems in the motor’s main circuit—such as loose wiring, corroded terminals, or burned-out components—can prevent current from flowing properly.

Power supply instability also plays a major role. Voltage fluctuations or insufficient input power can lead the frequency inverter to trip or underperform. Finally, if the motor’s encoder—responsible for feedback control—is damaged, the inverter will lose synchronization, resulting in erratic or non-responsive motor behavior.

By identifying which of these factors is at play, technicians can take precise corrective actions rather than trial-and-error replacements.

Step 1: Inspect the Control Signal Path

Control signals are the communication bridge between your control system and your inverter VFD. Any disruption can lead to loss of control. Begin by verifying that your input terminals are connected correctly according to the manufacturer’s wiring diagram. Use an oscilloscope or multimeter to monitor signal amplitude and waveform stability.

If the signal shows interference, introduce shielding cables or ferrite cores to reduce noise. For industrial environments with strong electromagnetic interference (EMI), grounding and cable segregation are essential. Also, confirm that your PLC or control module outputs proper logic levels compatible with your variable frequency drive input specifications.

Regular inspection of control wiring ensures that the VFD system maintains stable communication, enabling precise motor speed and torque control.

Step 2: Examine the Main Circuit and Motor Connections

The main circuit is the electrical backbone of any Variable Speed Drive (VSD). Faulty wiring or damaged components in this section often lead to control loss or irregular operation. Start by checking the output terminals (U, V, W) on the VFD to ensure that they are firmly connected to the motor. Look for signs of overheating, discoloration, or burnt insulation.

Next, measure the phase-to-phase resistance of the motor windings. Unequal readings may indicate winding faults or insulation breakdown. Additionally, inspect the circuit breaker, contactors, and protection devices between the frequency inverter and motor. Replace any worn or degraded parts.

Ensuring a clean, tight, and properly rated main circuit connection minimizes voltage drops and ensures that your variable frequency inverter can deliver full power to the load efficiently.

Step 3: Verify Input Power and Voltage Stability

Even the most advanced VFD cannot function correctly without stable power. Fluctuating input voltage, caused by grid instability, aged cables, or undersized transformers, can lead to undervoltage trips or reduced torque output.

To prevent this, measure the voltage at the variable frequency drive input terminals during both idle and load operation. Compare these values against the rated specifications. If the variation exceeds ±10%, consider installing a voltage stabilizer or upgrading the transformer capacity.

Maintaining a steady input power not only ensures reliable control but also extends the service life of your VFD inverter and connected motors.

Step 4: Inspect or Replace the Encoder

Encoders provide critical speed and position feedback to the inverter VFD, enabling precise closed-loop control. A damaged or misaligned encoder can cause unstable speed control or total loss of motor synchronization.

Check encoder wiring for continuity and correct polarity. If possible, use diagnostic software to monitor feedback signals in real time. Replace any encoder showing irregular pulse outputs or excessive noise.

High-quality encoders are particularly vital in solar pumping systems or industrial automation, where variable load conditions require consistent torque and speed regulation.

A healthy feedback loop ensures that the variable frequency drive maintains accurate performance, improving both productivity and energy efficiency.

Advanced Preventive Measures for Long-Term Stability

Beyond immediate fixes, preventive maintenance is key to ensuring your Variable Speed Drive (VSD) operates reliably. Establish a regular inspection schedule covering terminal connections, fan cooling systems, and software parameter backups.

Keep the VFD cabinet clean and well-ventilated to avoid overheating. Regularly update the firmware provided by your VFD manufacturer to optimize control algorithms and improve fault detection.

For environments with high humidity or dust, consider installing protective enclosures with IP54 or higher ratings. Continuous monitoring and maintenance greatly reduce downtime and extend equipment lifespan.

Partner with a Reliable VFD Manufacturer in China

Working with a professional variable frequency drive manufacturer ensures access to advanced engineering support, genuine parts, and consistent product quality.

As a leading VFD manufacturer in China, USFULL has specialized in Variable Frequency Drives (VFDs), Solar Pumping Inverters, and low-voltage protection devices since 2005. With ISO9001, CE, IEC, and TUV certifications, USFULL delivers reliable and customizable inverter solutions trusted by clients in over 90 countries.

Whether you’re seeking a VFD supplier for industrial automation, HVAC, or water pumping systems, USFULL provides robust and efficient products designed to meet global standards.

USFULL — Your trusted VFD partner for smarter, more stable power control.