Wrong VFD sizing leads to overheating, downtime, and costly replacements. To avoid failures, match HP, amps, and load—choose the right variable frequency drive.

Selecting the right HP variable frequency drive (VFD) means checking horsepower, motor amps, voltage, load type, and environment. A correct inverter VFD ensures efficiency, reliability, and long motor life while reducing energy costs.

Let’s break down the process of choosing the correct variable frequency inverter step by step for industrial applications.

What “HP” Means in VFD Sizing?

When most buyers ask for a “10 hp VFD,” they are usually thinking in terms of horsepower alone. While horsepower is an important metric, it only tells part of the story. VFDs—also called variable frequency inverters or Variable Speed Drives (VSDs)—are actually rated based on voltage and current (amps). Horsepower is simply the shorthand buyers often use, but it is not the full picture.

Here’s why:

For variable-torque loads such as pumps and fans, horsepower is usually sufficient when matched directly between motor and VFD.

For constant-torque loads such as conveyors or compressors, you may need to oversize your frequency inverter to handle initial torque or frequent start/stop cycles.

The full load amps (FLA) listed on the motor nameplate matter more than horsepower. A 10 hp motor with higher FLA requires a stronger drive compared to one with lower FLA, even at the same HP.

👉 In short, horsepower is your starting reference. To avoid premature failures, always cross-check with FLA and ensure the chosen variable frequency drive manufacturer provides accurate ratings.

Choosing Between 5 HP, 10 HP & 20 HP VFDs

Not all motors demand the same power. Choosing the correct VFD size ensures smooth performance and prevents energy waste. Let’s look at the three most common industrial categories:

5 HP Variable Frequency Drive

These compact drives are ideal for small pumps, light-duty conveyors, and basic HVAC systems. A 5 hp frequency inverter is cost-effective and works best in compact setups where space and budget are limited.

10 HP Variable Frequency Drive

The most versatile option, 10 hp VFDs fit mid-range applications such as irrigation systems, mixers, larger fans, and packaging lines. They balance cost and performance, making them the sweet spot for many industrial buyers.

20 HP Variable Frequency Drive

Designed for heavy-duty loads, these are perfect for compressors, chillers, multiple motor setups, or operations requiring high starting torque. A 20 hp variable frequency inverter may also be used to run several smaller motors if configured correctly.

By selecting the correct size, companies avoid underperformance or costly oversizing. A trusted VFD supplier can help analyze load requirements and recommend the optimal match.

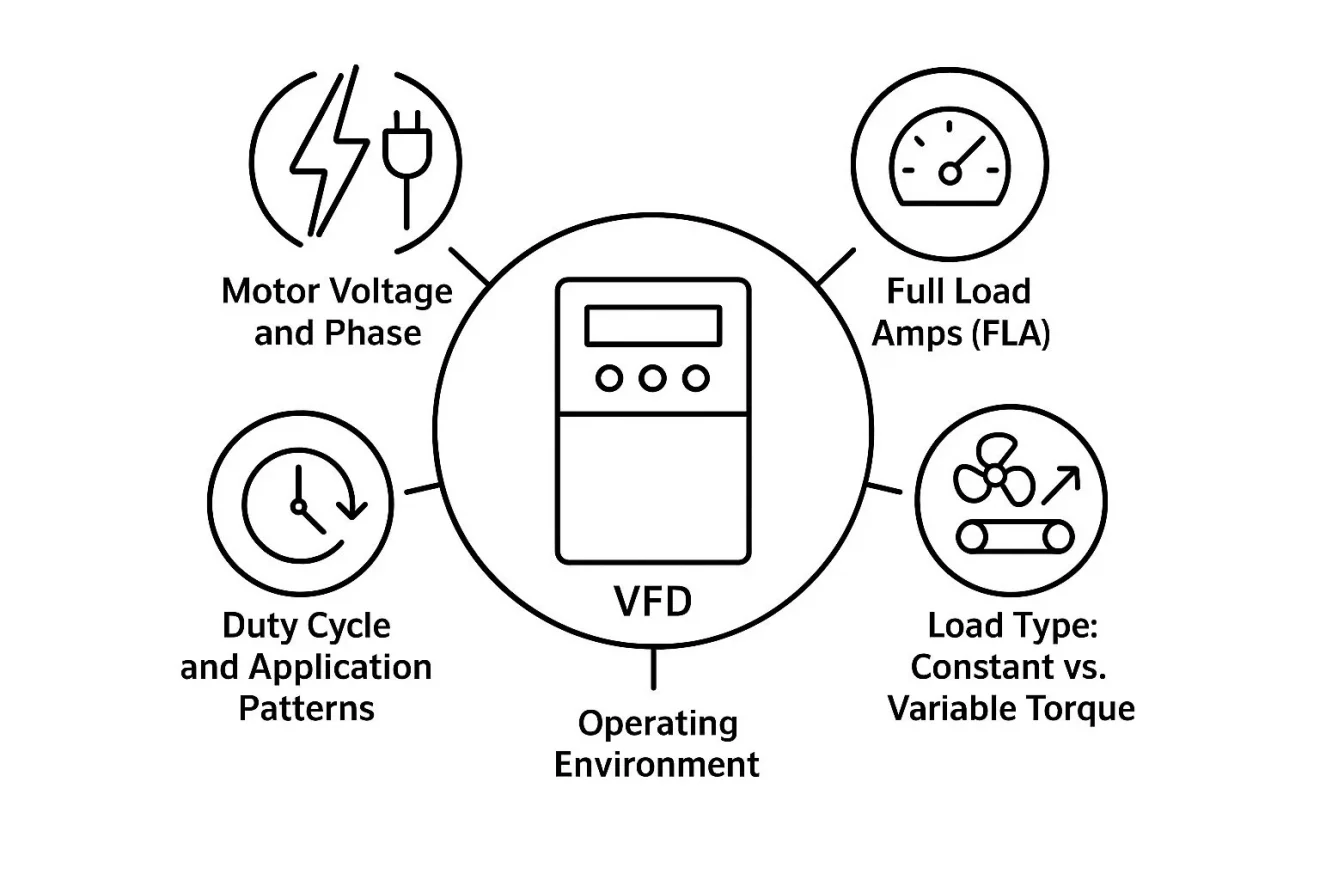

Key Factors in Variable Frequency Drive Selection

Selecting a frequency inverter isn’t just about horsepower. To ensure your investment pays off, consider the following factors:

1. Motor Voltage and Phase

Your inverter VFD must align with the motor’s voltage and phase. Most industrial motors use 3-phase 230 V or 460 V. A mismatch between motor and VFD can lead to overheating or permanent damage. If the input is single-phase, you may need to oversize the VFD or choose a dedicated single-phase compatible model.

2. Full Load Amps (FLA)

Check the motor’s nameplate for FLA. Horsepower tells you capacity, but amperage tells you the real demand. Always select a VFD that equals or slightly exceeds the FLA to prevent nuisance trips and breakdowns.

3. Load Type: Constant vs. Variable Torque

Fans and pumps (variable torque) consume less torque at lower speeds. A standard V/F VSD works perfectly. On the other hand, conveyors, crushers, or compressors (constant torque) require drives with higher overload capacity—typically 120–150%—to handle stress across all speeds.

4. Operating Environment

The location of installation is critical.

Indoor clean areas: IP20-rated drives are enough.

Dusty or humid factories: Choose IP55 or IP65 enclosures.

High-temperature zones: Look for derating specifications or drives with built-in cooling.

5. Duty Cycle and Application Patterns

Continuous applications can use VFDs that closely match motor HP. For motors with frequent on/off cycles or sudden heavy loads, oversizing by one class (e.g., from 10 hp to 15 hp) ensures stable operation.

By carefully balancing these factors, buyers protect their motors, reduce energy costs, and ensure smooth daily operations.

Selecting the right HP VFD for your motor requires more than matching horsepower. You must evaluate voltage, phase, FLA, load type, environment, and duty cycle. A 5 hp, 10 hp, or 20 hp frequency inverter can each be the right choice, depending on the application.

With decades of expertise as a VFD manufacturer in China, USFULL is ready to help you select the best variable frequency drive for your needs—ensuring efficiency, reliability, and cost savings.