When surge protective devices fail silently, they leave systems exposed to costly power damage. Ignoring SPD testing risks equipment failure — regular testing ensures lasting safety and performance.

To test a surge protective device (SPD), start with visual and safety inspections, then use a multimeter, insulation resistance tester, or professional SPD tester to measure continuity, voltage, and insulation. Record all test results, identify abnormal readings, and replace any faulty or aged SPDs to ensure consistent protection against DC surge, solar SPD, or PV SPD risks.

Understanding how to test surge protectors ensures your electrical system remains efficient, safe, and protected from unpredictable voltage surges.

Tools for Testing Surge Protection Devices

Testing surge protective devices (SPDs) requires precise tools to ensure accurate evaluation and safe operation. Each testing tool plays a unique role in detecting performance degradation and electrical faults. Whether you’re inspecting a DC SPD, solar SPD, or PV surge protector, having the right tools helps maintain stability and reliability in residential, commercial, and industrial systems.

Use a Multimeter for Testing

A multimeter is the most accessible tool for quick SPD testing. Set it to continuity mode to check internal connections; a steady beep indicates good continuity. In voltage mode, measure the input and output terminals of the SPD. Consistent readings across both confirm proper function. A multimeter cannot simulate real surge events but effectively detects basic issues in DC surge protector devices or solar surge protectors. Always disconnect power before testing to prevent shock hazards.

Insulation Resistance Tester

An insulation resistance tester measures the SPD’s ability to prevent current leakage between circuits. Connect the tester’s leads to the input and output terminals of the SPD and apply a standard voltage. A high resistance reading means good insulation, while a low one suggests internal deterioration. Regular insulation testing is critical for DC SPD and PV SPD systems exposed to high humidity or outdoor environments, ensuring long-term operational safety.

Professional SPD Tester

A professional SPD tester offers a comprehensive evaluation by simulating surge conditions similar to lightning strikes or switching transients. It measures clamping voltage, response time, and discharge capability. These parameters help determine whether the SPD can still absorb energy safely. For manufacturers or engineers working with solar surge protectors or industrial-grade DC surge protective devices, this tester provides the most reliable diagnostic data for preventive maintenance.

Additional Tools for Safe and Effective Testing

Beyond basic testers, advanced tools enhance accuracy and safety. A surge generator creates controlled overvoltage pulses to test SPD durability. A clamp meter measures real-time current without circuit disassembly. Thermal imaging cameras detect overheating, while oscilloscopes display waveforms for transient analysis. Using these tools ensures thorough assessment of every surge protective device in your system, minimizing downtime and ensuring compliance with international standards.

How to Test Surge Protection Devices?

Preparation Work: Safety Inspection and Setup

Before starting any test, prioritize safety. Ensure power is disconnected, confirm proper grounding, and follow standards such as IEC, UL 1449, and NEC. Proper grounding enables the SPD to divert surges safely. Inspect wires for tightness and corrosion, and position the SPD close to the protected equipment with short, straight connections to minimize resistance and improve surge response.

Use a Multimeter to Measure Continuity and Voltage

Switch your multimeter to continuity mode and touch the probes to the SPD terminals. A beep means good conductivity. Then, change to voltage mode and check both terminals. Consistent voltage values suggest the SPD is functioning; large differences indicate internal faults. This simple process helps verify the performance of DC surge protector devices and solar SPDs used in photovoltaic systems.

Test Insulation Resistance

Connect an insulation tester to the SPD and apply test voltage according to manufacturer specifications. Compare the readings to the acceptable range (usually above 50 MΩ). Low resistance values mean deteriorating insulation, which may cause current leakage or system instability. Regular insulation testing is especially critical for outdoor solar surge protectors and DC SPDs used in renewable installations.

Use a Professional SPD Tester for Advanced Evaluation

Attach the professional SPD tester according to the equipment manual. Choose a testing mode such as surge simulation or voltage clamping check. The tester will generate controlled surges and record response time and voltage suppression. If these values deviate from the standard, replacement is necessary. This method ensures accurate performance tracking for PV SPDs and industrial surge protective devices.

Record and Analyze Test Results

Recording results is crucial for preventive maintenance. Document test date, voltage levels, resistance readings, and test tools used. Compare data with previous records to identify performance degradation trends. Example parameters include:

Clamping Voltage: 400V (range 330V–450V)

Response Time: 1 ns (acceptable ≤ 2 ns)

Insulation Resistance: 100 MΩ (minimum 50 MΩ)

Continuous monitoring ensures that each SPD maintains effective surge protection throughout its service life.

Understanding Test Results

Signals of Success and Failure in Test Results

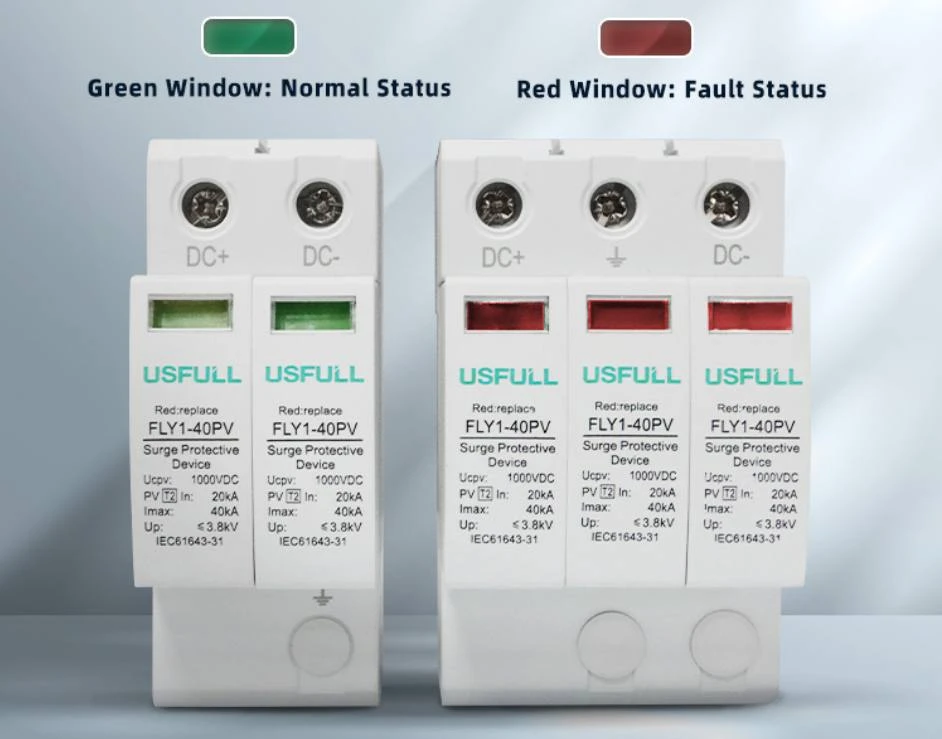

A successful test shows stable voltage, fast response, and high insulation resistance. Red or unlit indicators, irregular voltage, or low resistance signal SPD failure. During testing, ensure no sparks, noise, or excessive heat occur — these indicate internal component wear. A solar SPD or DC SPD that consistently fails to suppress surges should be replaced immediately.

Identifying Signs of SPD Damage or Malfunction

Look for cracks, discoloration, or burn marks on the SPD casing. Strange noises, frequent breaker trips, or inconsistent voltage readings also suggest internal failure. DC surge protectors exposed to harsh outdoor conditions may degrade faster, so inspect them monthly. Early detection prevents total protection loss and extends the lifespan of your surge protective device.

Deciding to Repair or Replace the SPD

Minor issues like loose terminals can be repaired, but significant internal damage or repeated surge activation requires replacement. Replace SPDs that have reached end of life or suffered multiple surges. For businesses using solar systems, replacing aging PV SPDs prevents costly downtime. Always choose certified replacements from a reputable surge protective device manufacturer in China such as USFULL, ensuring international compliance and long-term reliability.

Troubleshooting and Maintenance of Surge Protective Devices (SPDs)

Common Problems and Their Causes

SPDs may suffer from mechanical stress, moisture ingress, or dielectric breakdown. Weak spring pressure, poor sealing, or repeated partial discharges can cause flashovers and performance loss. Regular inspection helps detect such problems early, ensuring every solar surge protector or DC SPD operates safely under surge conditions.

Steps to Address Issues Identified During Testing

If testing reveals abnormalities, disconnect power, inspect all wiring, and clean internal parts with a dry cloth. Tighten loose terminals, dry any moisture, and replace damaged disks or components. After repairs, retest using a multimeter or SPD tester to confirm full recovery. Keeping a detailed repair log helps maintain reliability across all surge protective devices in operation.

Methods for Long-Term Maintenance of SPD

Implement a monthly inspection plan to check for heat, discoloration, or corrosion. Replace SPDs nearing their service life or showing frequent activation. Maintain detailed test and maintenance records. Partner with a trusted surge protective device supplier like USFULL, known for producing high-quality DC SPDs, PV SPDs, and solar surge protectors that meet IEC and TUV standards.