When induction motors can’t deliver torque at low speeds, systems stall, overheat, or fail—delaying production and damaging equipment. But with a well-matched VFD solution, stable 1Hz operation is possible.

Yes, you can technically run an induction motor at 1Hz using a VFD, but torque loss, heat buildup, and control instability make it risky. With the right setup—such as inverter-duty motors, external cooling, and closed-loop control—low-frequency operation becomes feasible for special applications.

Let’s dive deeper into the real limitations and professional solutions for running motors at ultra-low frequencies.

Can I Use a VFD on an Induction Motor?

Yes, variable frequency drives (VFDs), also called frequency inverters or Variable Speed Drives (VSDs), are widely used to control induction motors. These motors are commonly three-phase AC machines, and they respond well to the adjustable voltage and frequency output provided by VFDs.

Using a VFD allows for smooth speed control, soft start and stop, reduced energy consumption, and extended equipment lifespan. The inverter VFD adjusts motor speed by changing the output frequency from 0 Hz up to several hundred Hz. When paired with an inverter-duty motor, which has reinforced insulation and cooling, the combination becomes highly reliable.

However, to ensure compatibility, proper sizing, harmonic filtering, and attention to environmental conditions are essential. While single-phase motors typically require modifications, three-phase induction motors are an ideal match for variable frequency inverters.

What Is the Minimum Hz for a VFD?

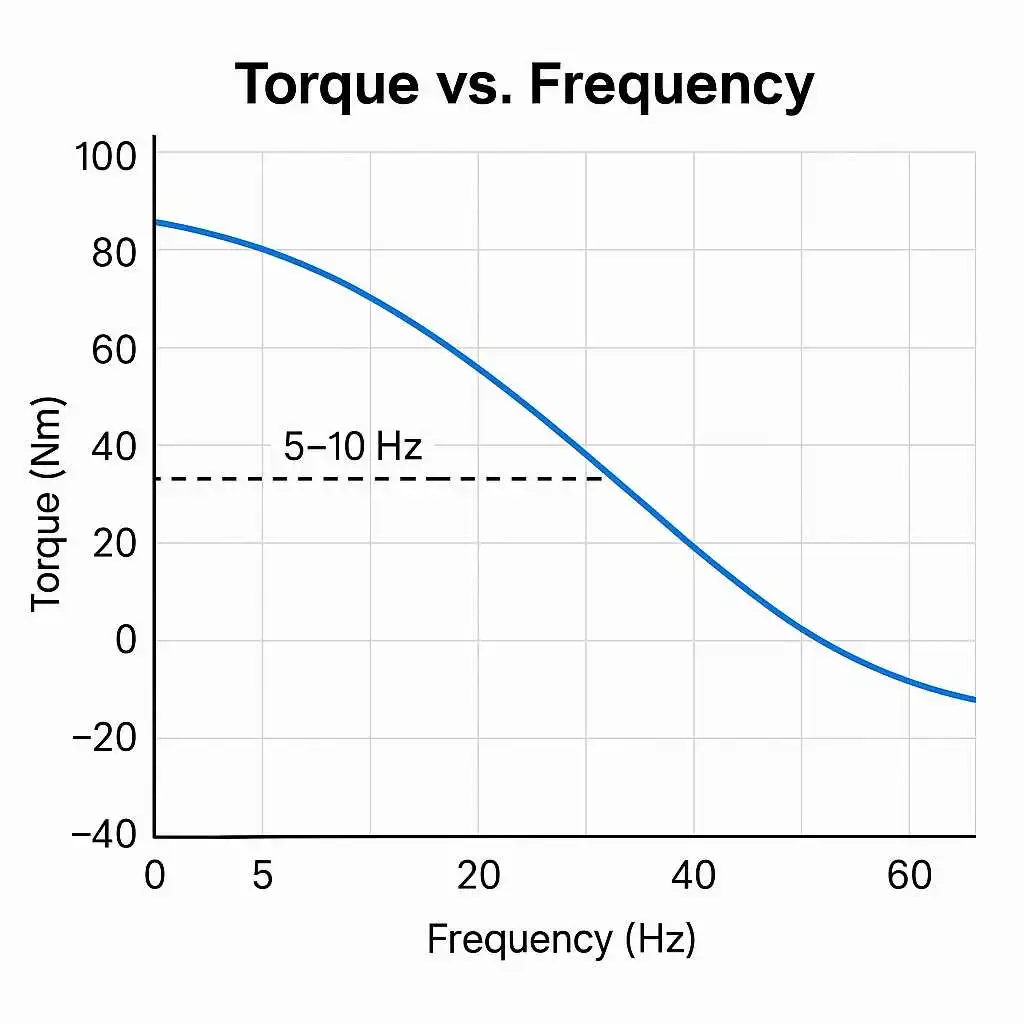

Most VFDs have a theoretical frequency output range from 0 Hz up to 400 Hz or more. But the practical minimum frequency for operating an induction motor is typically between 5 to 10 Hz. Running a motor at 1Hz presents several technical issues:

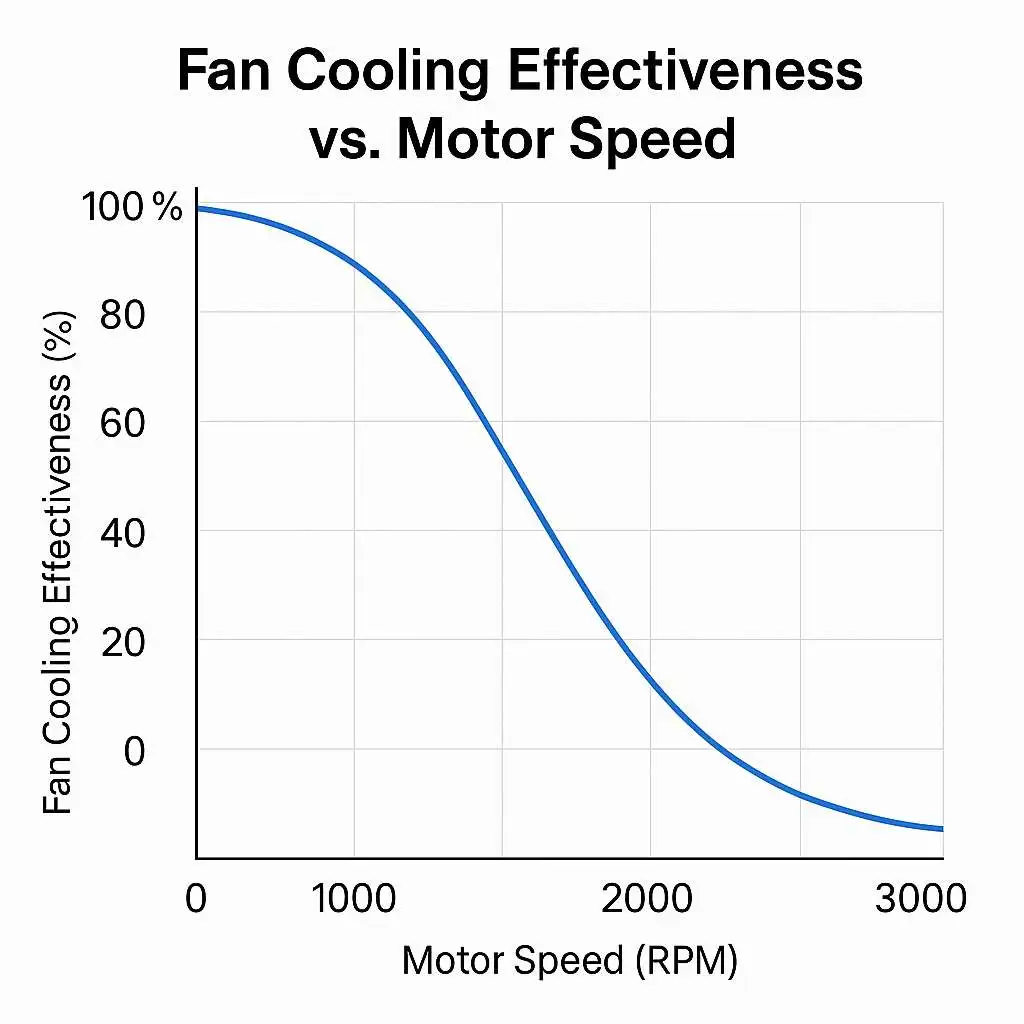

At low frequencies, the voltage supplied by the inverter VFD is proportionally low. This limits the magnetic flux and weakens torque production. The motor’s internal fan also rotates too slowly to provide adequate cooling, leading to overheating. Additionally, low-frequency control can result in torque ripple and unstable operation, especially in sensorless vector control modes.

To overcome these problems, external cooling fans, gear reducers, and encoder feedback systems can be implemented. For niche applications—like test benches or slow-positioning systems—these additions may justify the complexity.

What Is the Maximum Motor Speed for a VFD?

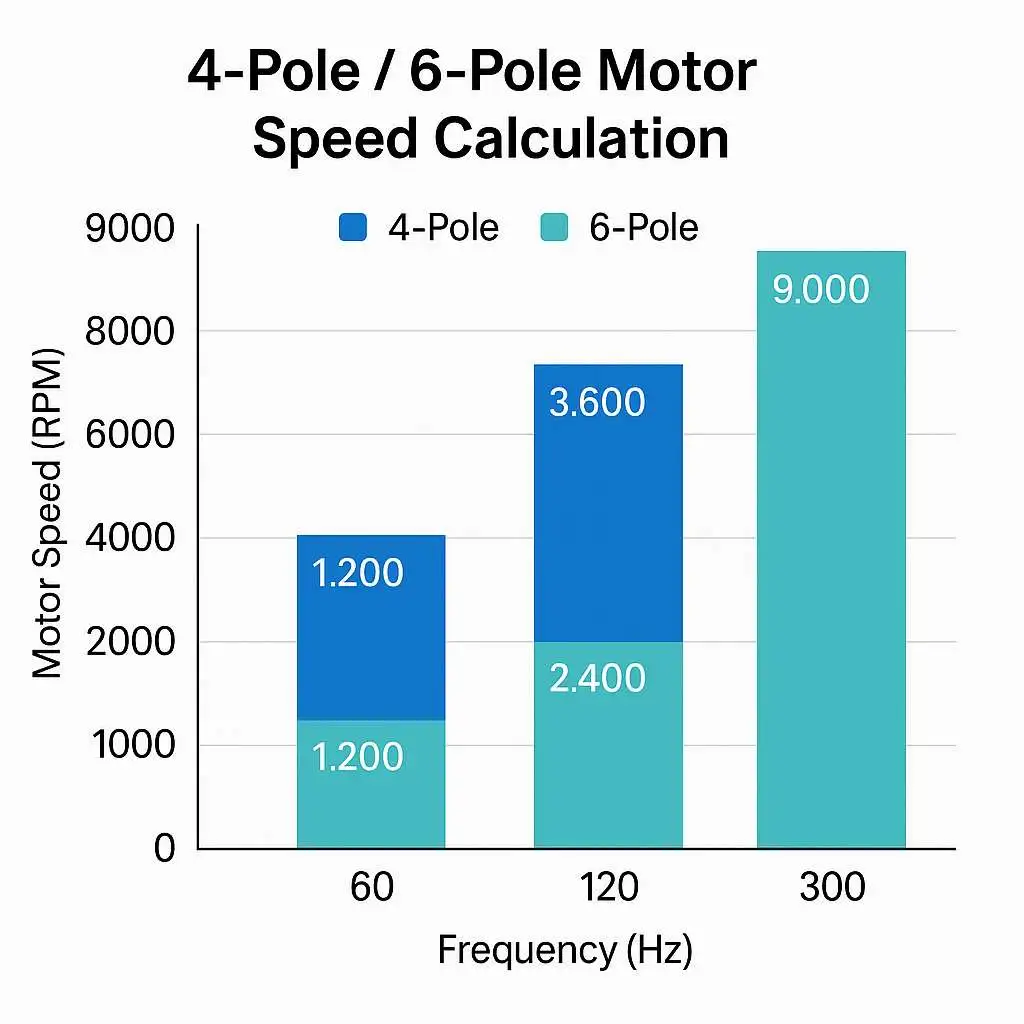

The maximum motor speed using a VFD is defined by two things: the drive’s maximum frequency output and the motor’s mechanical/electrical limitations. Many frequency inverters can output up to 400 Hz, but that doesn’t mean your motor can run that fast.

A standard 4-pole motor has a synchronous speed of 1800 RPM at 60 Hz. At 120 Hz, it would spin at 3600 RPM; at 300 Hz, 9000 RPM. However, pushing motors to these speeds can lead to excessive bearing wear, unbalanced rotors, and core losses due to the skin effect.

Therefore, VFD systems must be derated, and you should always consult the motor’s datasheet. High-speed applications like CNC spindles may require specialized high-speed motors with precision-balanced shafts and reinforced bearings. When carefully selected, the variable frequency inverter can safely extend your speed range while preserving performance.

Can a VFD Run Over 60 Hz?

Yes, VFDs (also known as frequency inverters or Variable Speed Drives) can be programmed to run well over 60 Hz. This capability is often used in industrial applications where high-speed rotation is necessary—such as centrifugal fans, grinders, or high-speed pumps.

However, when a variable frequency drive increases frequency beyond the motor’s base frequency (typically 50 or 60 Hz), voltage can no longer increase proportionally. This causes the torque to drop, even though speed rises. This range is known as the “constant power” region of operation.

It’s critical to ensure that the mechanical load and motor are designed for the resulting higher speeds. High-frequency operation can lead to dangerous overspeed, insulation breakdown, or premature mechanical failure. Always set upper frequency limits in the VFD parameters and use appropriate thermal monitoring.

Operating an induction motor at 1Hz with a VFD is possible, but only with careful engineering and application-specific adaptation.