Industrial motors often lack precise speed control. This leads to wasted energy, equipment wear, and production inefficiencies. The solution? Use a PLC with a VFD.

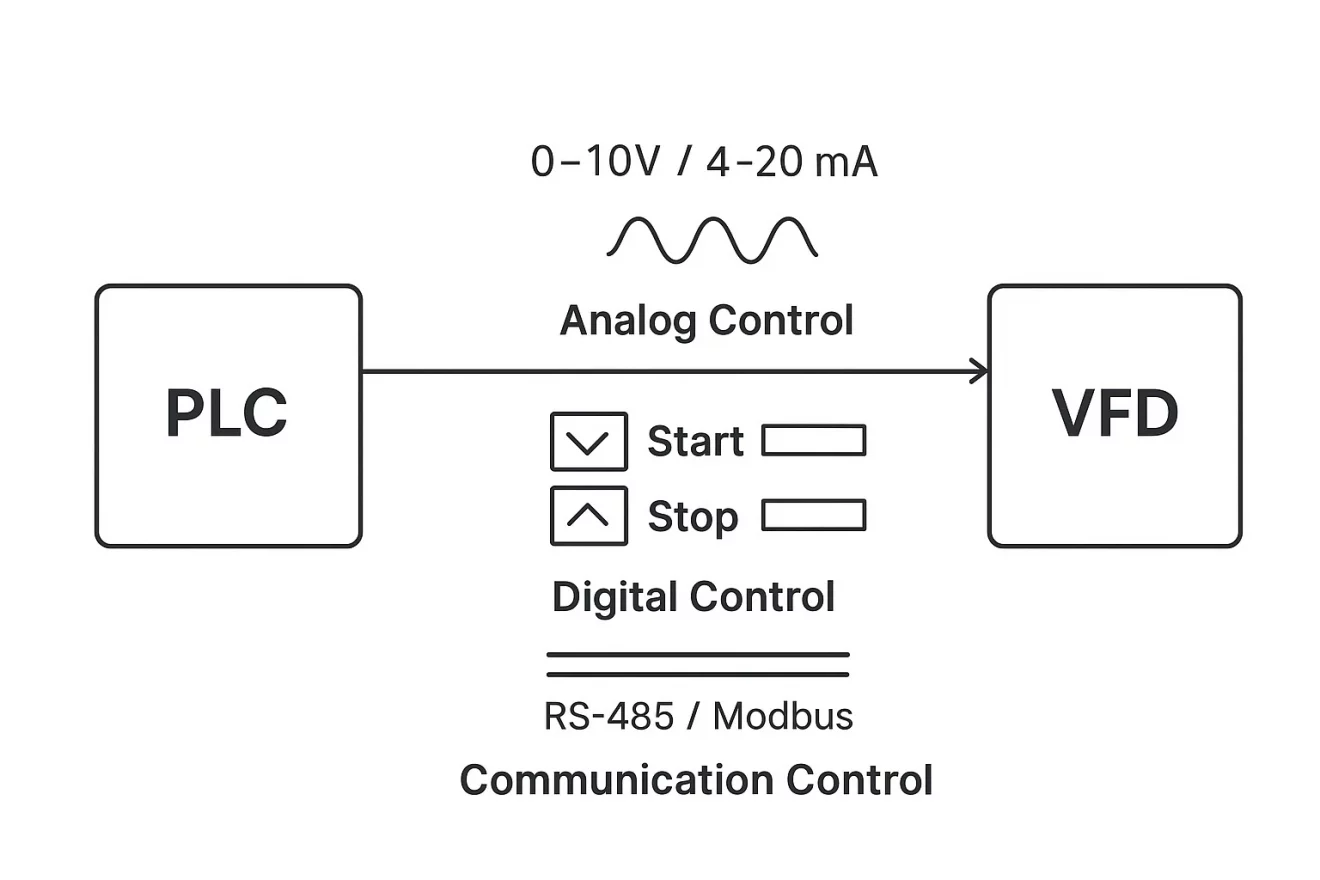

A Частотно-регулируемый привод (ЧРП) can be controlled by a PLC using three main methods: analog signal control, digital signal (switching) control, or communication protocols such as RS-485/Modbus. Each method offers different levels of precision, scalability, and flexibility for motor speed and process control.

PLC-VFD integration transforms automation efficiency. Let’s explore how it works, step by step.

What Is a Variable Frequency Drive (VFD)?

A Частотно-регулируемый привод (VFD), also called a преобразователь частоты, частотно-регулируемый инвертор, или Привод с переменной скоростью (VSD), is an electronic device that regulates motor speed by adjusting the frequency and voltage supplied to the motor. By changing these parameters, a VFD ensures smooth startup, energy savings, and precise speed control.

VFDs are widely used in pumps, fans, conveyors, and industrial automation systems. A reliable Производитель VFD в Китае can supply drives that meet global standards such as CE, IEC, and TUV certifications, ensuring long-lasting and safe operation in demanding environments.

Why Use a PLC to Control a VFD?

A Programmable Logic Controller (PLC) is designed to automate industrial processes through logic-based programming. When paired with a частотно-регулируемый привод, the PLC can manage motor speed, direction, and torque with greater precision.

Without a PLC, operators often rely on manual inputs or fixed settings on the VFD, which limits flexibility. By using a PLC, engineers can automate speed adjustments based on sensors, time schedules, or process requirements. This leads to better energy efficiency, improved safety, and reduced human error.

The Main Methods to Control a VFD with a PLC

There are three primary ways to connect a PLC to a преобразователь частоты:

1. Analog Signal Control

PLC analog output modules can send a voltage (0–10V) or current (4–20mA) signal to the VFD. The drive interprets this signal as a command for motor speed.

This method allows smooth and continuous speed adjustment, making it suitable for applications like water pumps or conveyors that require variable speed. However, analog signals are sensitive to noise interference and voltage drops over long distances, which can reduce accuracy.

2. Digital Signal (Switching) Control

PLC digital outputs are connected directly to the VFD’s control terminals (e.g., Start, Stop, Forward, Reverse). This setup lets the PLC turn the motor on or off, switch between directions, and select preset speeds.

Although limited to step-by-step (multi-speed) adjustments instead of continuous variation, digital control is highly reliable, cost-effective, and ideal for systems where only a few speed options are needed.

3. Communication Protocol Control (RS-485/Modbus)

Modern VFDs and PLCs often support communication standards such as RS-485 с Modbus RTU protocol. In this setup, a single PLC can control multiple VFDs using just a communication cable.

This method is highly scalable and cost-efficient, as it eliminates the need for numerous analog or digital I/O points. It also allows advanced data exchange, such as motor status monitoring, fault diagnostics, and energy consumption reporting.

Step-by-Step Guide: PLC Controlling a VFD

Hardware Wiring – Connect PLC analog/digital outputs or RS-485 terminals to the VFD input.

VFD Parameter Settings – Configure operation mode (external control), acceleration/deceleration times, and motor protection limits.

PLC Programming – Write ladder logic or structured text to manage start/stop commands, speed references, and direction.

Testing and Tuning – Run trial operations to fine-tune speed control, ramp times, and error handling.

System Integration – Combine with sensors, SCADA, or HMI for a complete automation solution.

By following these steps, engineers can achieve seamless communication between a PLC and an inverter VFD.

Common Applications of PLC-VFD Integration

Water Pumping Systems – Maintain constant pressure by adjusting motor speed in real time.

Системы отопления, вентиляции и кондиционирования воздуха – Improve energy efficiency by regulating fan and compressor speed.

Conveyor Belts – Control start/stop sequences and adjust speed based on production demand.

Irrigation Systems – In solar water pumps, a solar pumping inverter (specialized VFD) controlled by a PLC ensures optimal water delivery.

Such flexibility explains why manufacturers, suppliers, and automation engineers worldwide rely on this integration for both cost savings and performance optimization.

Использование PLC to control a variable frequency drive unlocks smarter automation, better energy savings, and enhanced process reliability. Whether through analog, digital, or RS-485 communication, the choice depends on your application needs.

By partnering with a reliable Производитель VFD like USFULL, businesses can integrate high-quality drives with PLC systems seamlessly—ensuring productivity, efficiency, and long-term success.