Unexpected VFD load drops cause instability, equipment damage, and production losses. The solution lies in robust inverter design, preventive maintenance, and reliable VFD manufacturer support.

A sudden load drop in a variable frequency drive (VFD) leads to voltage surges, current oscillations, and mechanical stress, often causing overvoltage faults, component wear, or inverter VFD shutdowns.

Let’s explore how sudden load drops impact VFDs and discover practical prevention strategies to protect your frequency inverter investment.

Voltage Surge and Overvoltage Risks

When a load disconnects suddenly, the motor continues spinning due to inertia, effectively acting as a generator. The kinetic energy is converted into electrical energy, which feeds back into the DC bus of the frequency inverter. Without braking units or energy recovery systems, the DC voltage rises sharply. In severe cases, it can exceed rated values by 50%, leading to overvoltage trips or even damage to IGBT modules.

For example, in textile machinery, if thread breaks suddenly and the motor loses load, the inverter VFD may trigger repeated “OU” (overvoltage) alarms. Prolonged exposure increases the risk of catastrophic failure. Choosing a reliable VFD manufacturer in China that integrates advanced protection functions can significantly reduce such risks.

Current Oscillation and Control Instability

Load variations affect current regulation loops in variable speed drives (VSD). When the load suddenly drops from full load to near zero, the VFD output current can oscillate at high frequency. This creates multiple issues:

False overcurrent protection triggering

Distorted PWM signals that cause uneven heating of switching transistors

Reduced accuracy in vector control algorithms

These instabilities not only affect the inverter’s performance but also shorten its lifespan. High-quality variable frequency inverter models use optimized control software to maintain stability during sudden changes. Leading VFD suppliers also provide adaptive algorithms that help maintain precise torque and speed regulation.

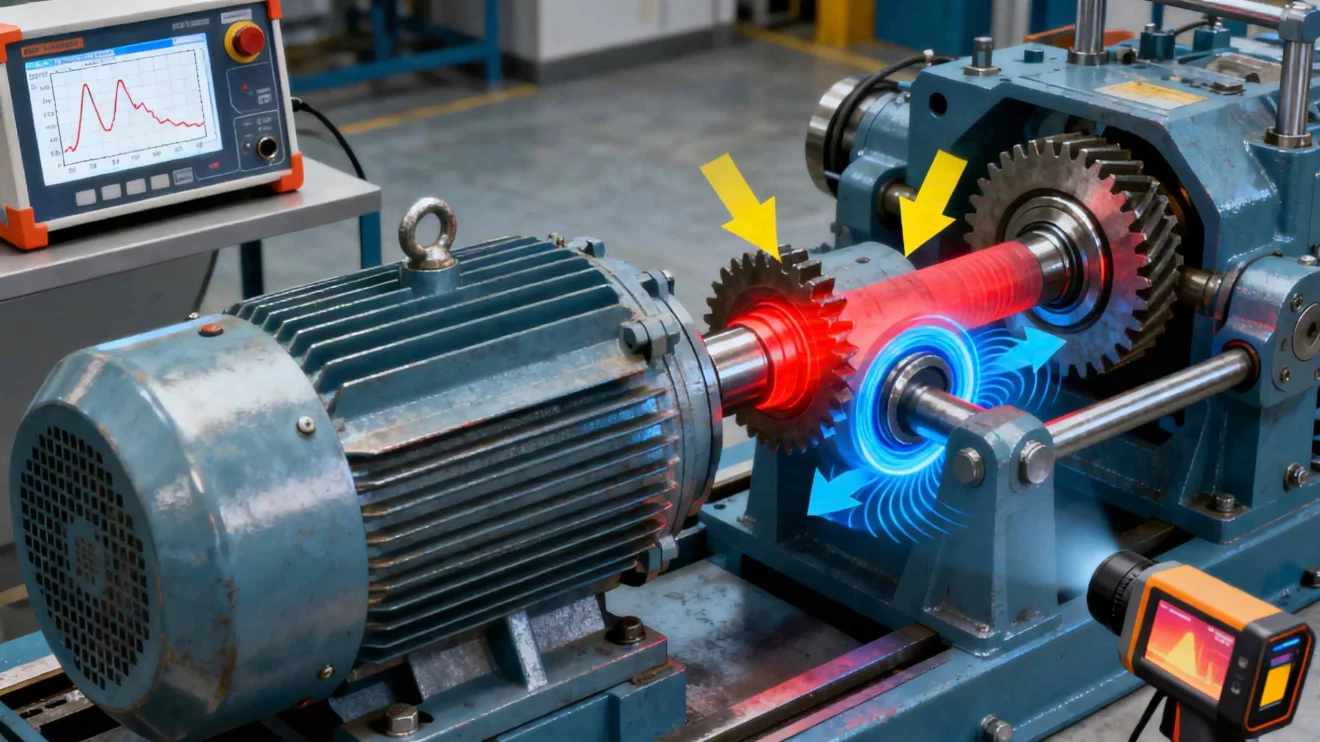

Mechanical Stress on Motors and Systems

Beyond electrical disturbances, sudden load drops can stress mechanical components. For example, in pumps or fans with large inertia, a sudden disconnection may cause the motor to overspeed. At 130% of the rated RPM, bearings wear prematurely, and shafts may misalign. In industrial environments, this mechanical impact can translate to unplanned downtime and higher maintenance costs.

Partnering with a variable frequency drive manufacturer that designs systems with built-in mechanical protection functions—such as speed tracking, restart, and torque limits—helps minimize long-term damage.

Hidden Long-Term Damage

Sudden load drops may not always cause immediate failure, but repeated incidents create hidden risks:

Capacitor Aging – DC bus capacitors face accelerated wear under frequent overvoltage. Studies show exceeding rated voltage by just 10% can reduce capacitor lifespan by 30%.

Software Malfunctions – Self-tuning PID controls in advanced frequency inverters may become unstable after frequent load shocks.

Cooling Imbalance – Cooling fans continue running at high speed even after load reduction, potentially causing condensation and corrosion inside the VFD.

This highlights why preventive design and reliable component sourcing from a trusted VFD supplier matter greatly in protecting your investment.

Typical Failure Modes from Load Drops

Statistics show that sudden load drops trigger a variety of VFD issues:

Overvoltage faults (42%): frequent alarms and downtime

IGBT damage (28%): output phase imbalance or direct short circuit

Capacitor bulging (17%): higher DC bus ripple current

Control board failure (13%): data loss or communication errors

Understanding these failure modes allows engineers to implement better diagnostic and preventive maintenance strategies. Using a variable speed drive designed by an experienced VFD manufacturer in China ensures stronger protection and resilience.

| Fault Type | Proportion | Typical Manifestation |

| Overvoltage Protection | 42% | Frequent appearance of E.OU / E.F fault codes |

| IGBT Damage | 28% | Unbalanced three-phase output or direct short circuit |

| Capacitor Bulging | 17% | Increased ripple on the DC bus |

| Control Board Failure | 13% | Parameter loss or communication interruption |

Engineering Protection Strategies

Effective solutions to sudden load drop challenges exist at multiple levels:

Hardware: Install braking resistors (15–20% of motor rated power) or regenerative feedback units for energy recovery.

Parameters: Extend deceleration times, enable overvoltage stall prevention, and activate speed tracking restart.

System Design: Add mechanical interlocks, multiple voltage sensors, and predictive diagnostics.

Selecting a variable frequency drive manufacturer that provides flexible configuration options is key to customizing protection strategies for different industries.

Maintenance and Modernization Practices

Operational reliability depends not only on design but also on proper maintenance:

Measure the capacitor ESR monthly to detect early aging

Clean cooling systems quarterly to avoid dust buildup

Calibrate voltage sensors annually for accuracy

Immediately cut power and inspect braking resistors after a sudden load drop

For older installations, modernization is essential. Options include flywheel energy storage, hybrid DC bus capacitors, or SiC-based switching components for higher efficiency and durability. A VFD supplier with strong R&D capabilities can provide tailored upgrade solutions.

A sudden load drop on a VFD is more than a temporary disturbance—it can shorten component lifespan, destabilize processes, and increase costs. Prevention requires a multi-layered strategy: robust design, precise parameter settings, and ongoing maintenance.

Working with an experienced VFD manufacturer in China like USFULL ensures your variable frequency drive system remains reliable even under demanding and unpredictable conditions.