Poor equipment selection causes inefficiency, higher costs, and downtime. This risks missed deadlines and lost profits. Choosing VFD or MCC wisely solves this.

A Variable Frequency Drive (VFD) controls the speed of a motor by adjusting supply frequency and voltage, while a Motor Control Center (MCC) is a centralized assembly housing multiple motor control units for managing several motors simultaneously.

Let’s explore their differences, applications, and why smart buyers choose the right solution for their industrial needs.

What Is the Difference Between an MCC and a VFD Panel?

An MCC (Motor Control Center) is a large, modular assembly that contains multiple compartments (often called “buckets”) for controlling and protecting motors. These compartments may include contactors, overload relays, soft starters, and even Variable Frequency Drives (VFDs). MCCs are used in large industrial facilities as a central hub for distributing power and managing several motors from a single location. Their standardized design allows easy maintenance, expansion, and integration with automation systems.

In contrast, a VFD panel—also known as a Variable Speed Drive (VSD), frequency inverter, or variable frequency inverter panel—is a dedicated enclosure housing a VFD and its associated components, such as input disconnect switches, fuses or breakers, line reactors, EMI filters, and operator controls. It’s designed to precisely adjust motor speed and torque, optimizing performance, reducing energy consumption, and prolonging equipment life.

Key difference: MCCs focus on centralized management of multiple motors, while a VFD panel is typically built for controlling one motor (or a small group) with advanced speed control features. A VFD manufacturer in China like USFULL often supplies both options to match different project scales and budgets.

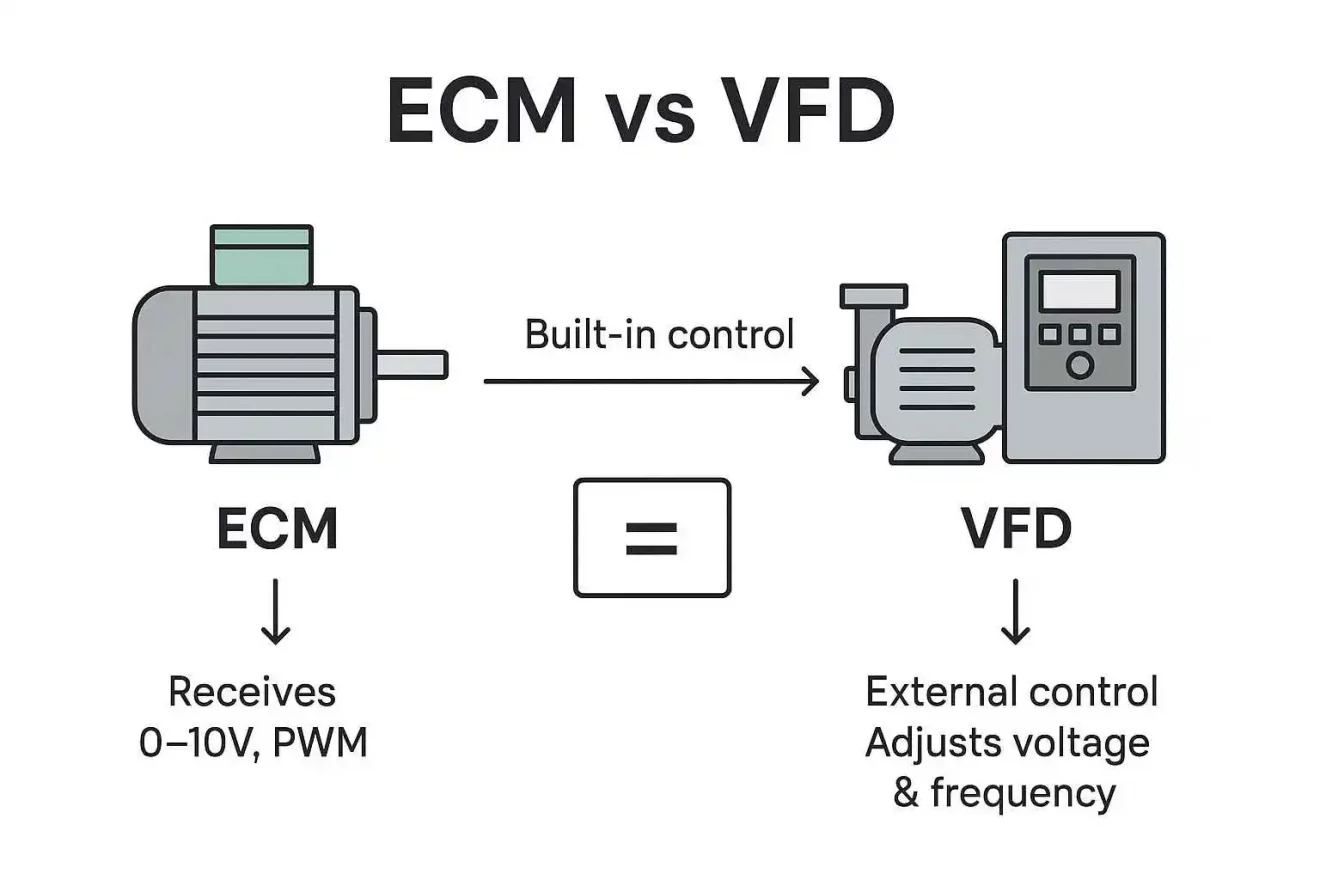

What Is the Difference Between an Electronically Commutated Motor (ECM) and a VFD?

An Electronically Commutated Motor (ECM) is a high-efficiency brushless DC motor with integrated electronics that manage commutation and speed control internally. It doesn’t require an external drive—its speed is regulated through built-in circuits responding to control signals such as 0–10V, PWM, or digital commands. ECMs are popular in HVAC applications, refrigeration units, and systems where compactness and built-in efficiency are critical.

A VFD, on the other hand, is an external device used with standard AC induction motors to vary the supply frequency and voltage. This allows operators to control speed, torque, and acceleration profiles. The flexibility of a VFD, also called an inverter VFD or VSD, means it can be paired with many motor types, making it ideal for industrial retrofits, pumping systems, and conveyor lines.

Core difference: ECMs integrate control within the motor itself, while VFDs provide external, adjustable control for standard motors. A variable frequency drive manufacturer can supply VFDs for a wide range of applications, while ECMs are purchased as complete motor units.

What Is the Difference Between a Motor Control Center and a Motor Control Panel?

A Motor Control Center (MCC) is a large-scale, centralized installation designed to manage and protect multiple motors in industrial environments. Built according to NEMA or IEC standards, MCCs can host dozens of motor starters, feeders, and VFDs in one place, making them ideal for complex facilities such as manufacturing plants, water treatment plants, and large-scale pumping systems.

A motor control panel is much smaller and typically handles one motor or a small group of motors. It may include a single starter, overload relay, or even a small variable frequency drive for speed regulation. Motor control panels are commonly used for localized equipment like small pumps, fans, or mixers, where centralized control is not required.

While MCCs are about scalability and centralization, motor control panels focus on simplicity and localized function. Many VFD suppliers offer both MCC integration services and standalone motor control panel solutions, ensuring flexibility in project design.

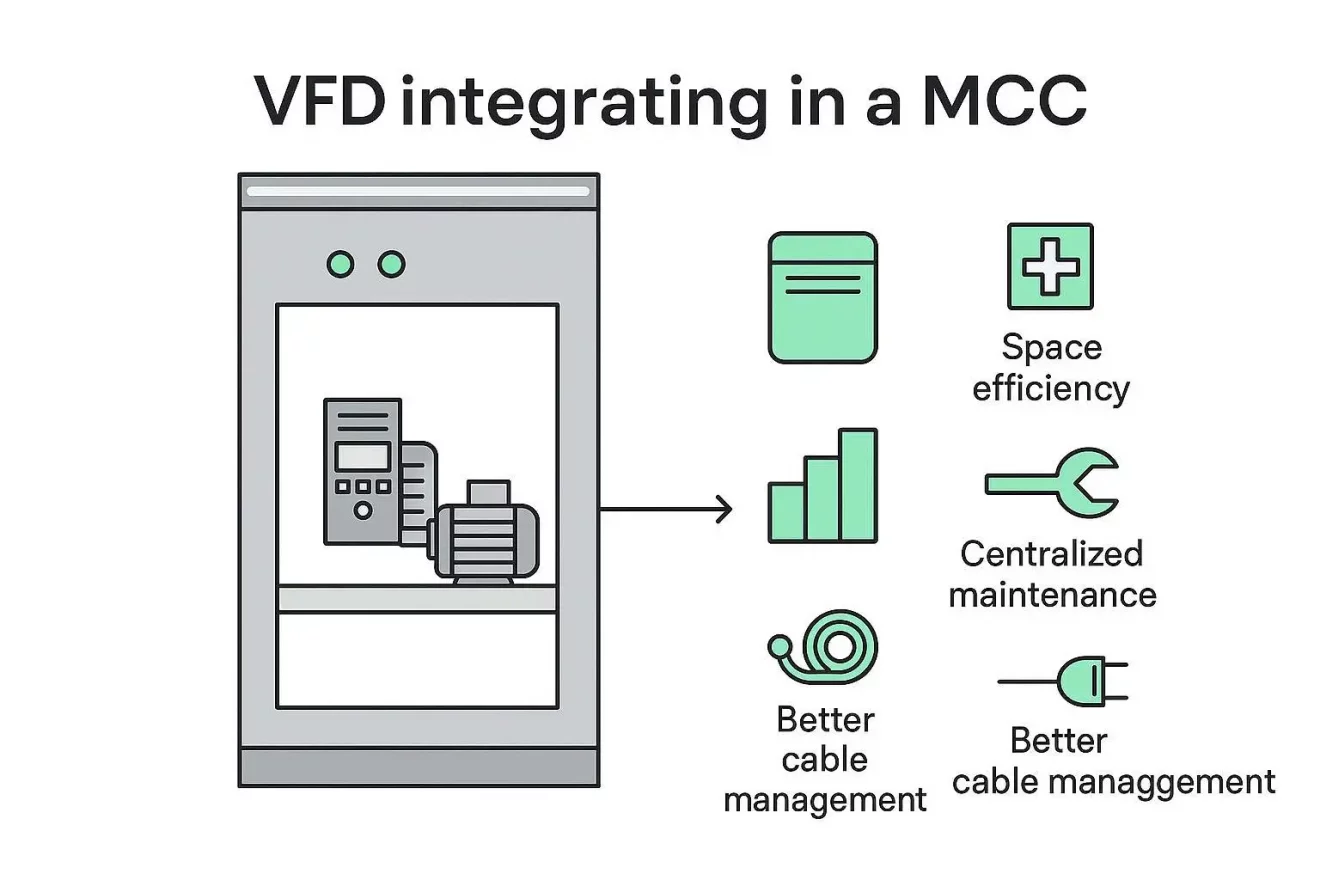

Can You Put a VFD in an MCC?

Yes. In fact, integrating a Variable Frequency Drive into an MCC is now common practice in modern industrial systems. This approach combines the organizational benefits of centralized motor management with the efficiency and control advantages of a VFD.

MCC sections designed for VFDs include proper ventilation, harmonic filters, line reactors, and space for communication modules. This ensures reliable performance, minimal interference with other equipment, and compliance with energy efficiency regulations.

Advantages of integrating a VFD in an MCC include:

Space efficiency: Eliminates separate panels for drives.

Centralized maintenance: All motor control equipment is in one location.

Energy savings: Variable speed operation reduces energy consumption.

Better cable management: Shorter cable runs between control and motor compartments.

Why Choosing the Right Equipment Matters

Selecting between an MCC, VFD panel, ECM, or motor control panel depends on the size, complexity, and goals of your project. Using the wrong setup can lead to:

Higher operating costs due to inefficiency.

More downtime from overheating or poor control.

Missed production targets due to inflexible motor control.

Partnering with an experienced variable frequency drive manufacturer ensures you get expert advice, certified products, and configurations suited to your application.

MCCs manage multiple motors centrally, while VFDs provide precision speed control for individual motors.