Faulty electrolytic capacitors in your variable frequency drive (VFD) lead to downtime, equipment failure, and costly repairs — but understanding the causes helps you prevent damage and extend lifespan.

Electrolytic capacitors in variable frequency inverters often fail due to overvoltage, overheating, poor-quality components, or incorrect installation, which results in reduced VFD efficiency, system instability, and potential equipment shutdown. Regular maintenance and proper selection can greatly reduce these failures.

Keep reading to uncover the exact reasons behind capacitor failures and learn practical solutions to safeguard your VFD system.

What Are Electrolytic Capacitors and Why Are They Important in VFDs?

Electrolytic capacitors are critical components inside a variable frequency drive (VFD) or variable speed drive (VSD). They smooth out the DC voltage after rectification, filtering out ripples and ensuring the inverter stage receives stable power. Without properly functioning capacitors, your variable frequency inverter cannot deliver smooth, adjustable power to the motor.

The role of these capacitors is especially crucial because VFDs operate in demanding environments, with constant high-frequency switching, thermal stress, and electrical fluctuations. Even minor defects or capacity losses in these capacitors can lead to reduced energy efficiency, motor vibrations, and even full system shutdowns.

What Causes Filter Electrolytic Capacitors to Fail in a Variable Frequency Drive?

Several factors contribute to the failure of electrolytic capacitors in variable frequency drives:

✅ Overvoltage or Voltage Spikes: Capacitors are rated for specific voltage levels. When input voltage exceeds these ratings, often due to power grid fluctuations or switching surges, the dielectric inside the capacitor breaks down, leading to short circuits or explosions.

✅ Overheating and Poor Ventilation: A variable frequency inverter generates heat during operation, and inadequate cooling can cause capacitor temperatures to rise beyond safe limits. Elevated temperatures accelerate electrolyte evaporation, reduce capacitance, and increase leakage current, leading to premature failure.

✅ Poor Component Quality: Low-cost or substandard capacitors with poor sealing, impure electrolyte, or low endurance ratings will degrade faster, especially in high-stress VFD environments. High-quality components designed for industrial use last significantly longer.

✅ Incorrect Installation or Connection: Improper mounting, reversed polarity, loose connections, or using incompatible replacements can increase ESR (equivalent series resistance) or cause mechanical stress, resulting in localized heating and failure.

✅ Aging and Natural Wear: Over years of operation, capacitors naturally lose capacitance due to electrolyte drying, especially if operated close to their maximum ratings. Without regular maintenance checks, aged capacitors can silently degrade until sudden failure occurs.

How to Identify If VFD Filter Electrolytic Capacitors Are Damaged?

Technicians can identify failing capacitors in a variable frequency drive VFD by:

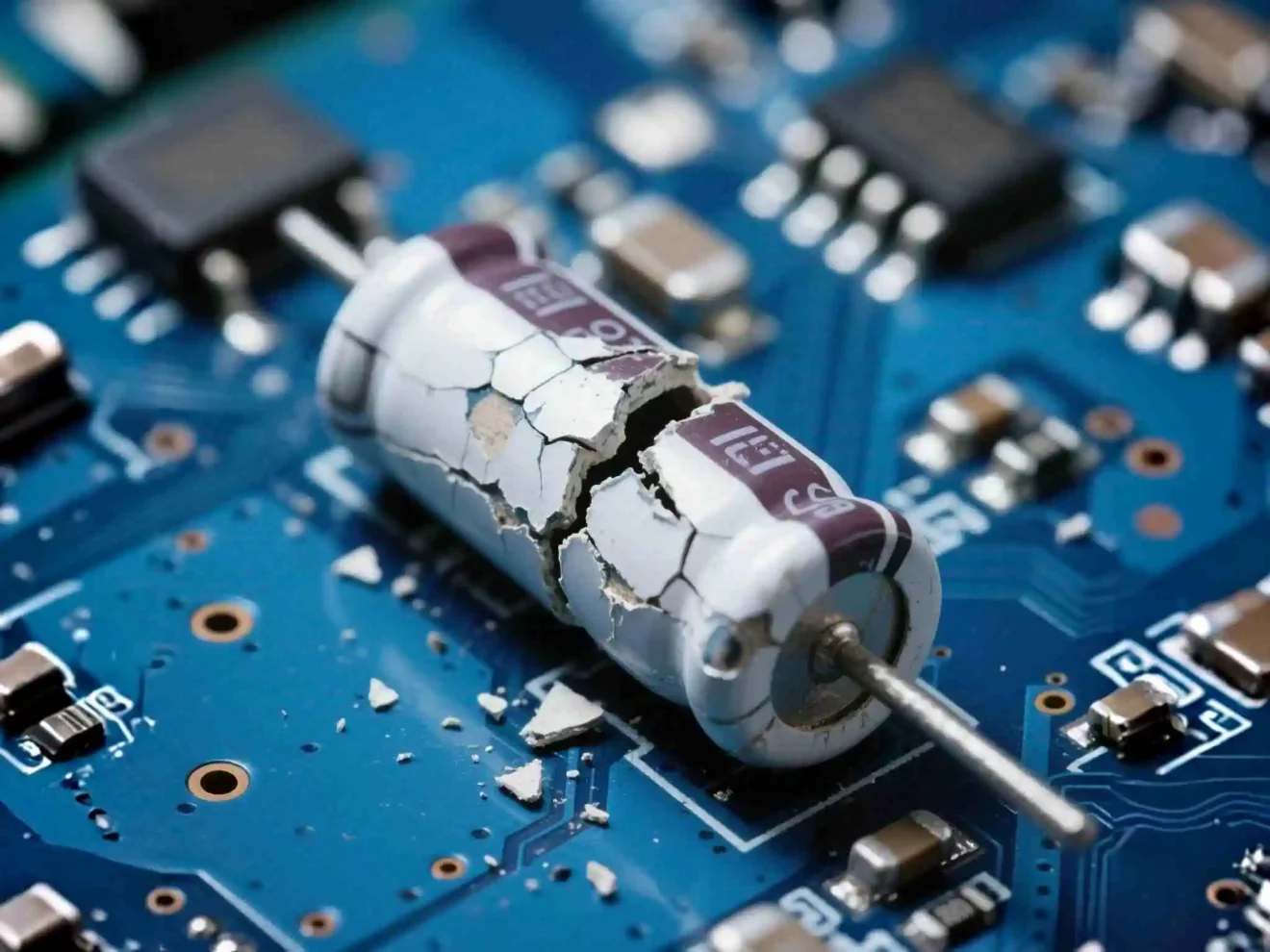

Visual Inspection: Look for bulging tops, cracked plastic sleeves, leaked electrolyte, or corrosion on terminals.

Electrical Testing: Use a multimeter or ESR meter to check for open circuits, shorts, or significantly reduced capacitance.

Operational Symptoms: Notice increased motor noise, reduced torque, fluctuating output voltage, or frequent system trips — these often point to deteriorating capacitor performance.

Regular inspections can catch early-stage failures, preventing costly downtime.

What Are the Consequences of Ignoring Failing Capacitors in Variable Frequency Inverters?

Neglecting failing electrolytic capacitors can result in:

Complete System Shutdown: Capacitor failure can short the DC bus or trip the inverter, halting production.

Damage to Other Components: Overstressed capacitors may cause overcurrent or voltage spikes, damaging sensitive IGBTs, diodes, or control boards inside the VFD.

Reduced Energy Efficiency: Without proper filtering, the VFD’s output becomes noisy and inefficient, raising energy costs.

Increased Maintenance Costs: Ignoring capacitor health can lead to more expensive repairs or the need for full unit replacement.

How to Prevent Electrolytic Capacitor Failures in Variable Speed Drives?

To extend the life of your variable speed drive (VSD) capacitors, follow these best practices:

✅ Use Quality Components: Always source capacitors from reputable manufacturers with ratings suited to your VFD’s voltage, ripple current, and temperature demands.

✅ Ensure Proper Cooling: Maintain clean ventilation paths, monitor ambient temperatures, and replace clogged filters or faulty fans to keep internal temperatures within specifications.

✅ Monitor Operating Conditions: Use surge protection, stabilize input voltages, and avoid pushing the VFD to its absolute limits to reduce stress on internal components.

✅ Schedule Regular Maintenance: Periodically check capacitance, ESR, and visual condition. Replace capacitors proactively before end-of-life.

✅ Install Correctly: Follow manufacturer guidelines for mounting, connection, and tightening torque to prevent mechanical or electrical stress.

Why Is Choosing the Right VFD Supplier Critical for Capacitor Reliability?

Selecting a reliable supplier like USFULL, with certified manufacturing processes, quality control, and tested components, significantly reduces the risk of premature capacitor failure. Low-cost suppliers may cut corners on capacitor quality or assembly, leading to unexpected breakdowns, whereas proven manufacturers use capacitors rated for long service life, ensuring better system stability and lower long-term costs.